by ATLant1c-pKg | Sep 2, 2022 | Packaging Equipment and Materials

The Guardian Taping System automatically and optimally applies the perfect amount of high-quality tape to every package that comes down the production line. The program saves you money through reduction of… • Material Usage and Waste • Downtime • Damage • Manual...

by ATLant1c-pKg | Mar 7, 2022 | Packaging Equipment and Materials, Printing and Graphics, Uncategorized

https://vimeo.com/673225237/de53c47f88 Atlantic has installed a LithoFlash Inline Scanner on its KBA 162 large format printing press. In the video above, Casey Ellison and Allison Scales give an inside look at Atlantic’s Printing & Graphics location in Tabor City,...

by ATLant1c-pKg | Feb 22, 2022 | Package Design and Testing, Packaging Equipment and Materials

Atlantic’s Film Lab in Charlotte, North Carolina, provides customers with data-driven solutions that reduce product damage and save money. We provide our partners with thorough testing and hands-on training to ensure stretch films, trash bags, shrink films, and meat...

by ATLant1c-pKg | Mar 3, 2020 | Packaging Equipment and Materials, Poultry Equipment Spotlight

Taping may seem like one of the more basic functions you perform in your facility. But if you have tape that fails, or a tape head system that fails to apply the tape properly, then you have big problems. Broken seals lead to broken cases, and broken cases on a...

by ATLant1c-pKg | Jan 16, 2019 | Packaging Equipment and Materials, Poultry Equipment Spotlight

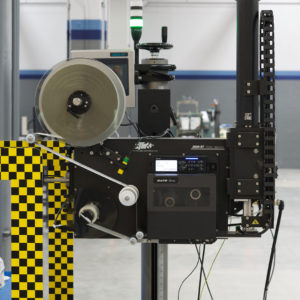

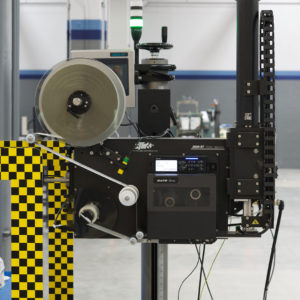

SPOTLIGHT ON THE CTM LABEL APPLICATOR Choosing the right label applicator for your packaging line will bring several advantages. It will streamline your process while providing consistent output and lowering costs overall. For our poultry customers at Atlantic, we...

by ATLant1c-pKg | Dec 11, 2018 | Packaging Equipment and Materials, Poultry Equipment Spotlight

Spotlight on the Pattyn Poly Bag Inserter To help automate your packaging line, the Flexim-31 Poly Bag Inserter from Pattyn makes made-to-measure bags from a roll of polyethylene film and automatically inserts the bags into different types of containers: cardboard...