Also check out our Sustainability Terms Glossary, where we’ll add key terms from each of our Deep Dives over time. Bookmark this page for future reference!

Over the past few years, you’ve probably seen a spike in bioplastics, biodegradable or just “degradable” packaging, and compostable packaging. While these terms are often used interchangeably, they refer to different things, and deciphering whether they’re “sustainable” or not can be complicated. This blog post will take a deep dive into what these different terms mean and how we think about them from a sustainability point of view.

Before jumping in: why are bioplastics and compostables being used more?

We’ve all become more aware over the last several years that traditional, petroleum-based plastic may be very effective as a packaging material, but it poses many challenges in its manufacturing and end-of-life (EOL). For the sake of brevity in this Deep Dive, we’ll just refer to traditional, petroleum-based plastic as “plastic.” Those challenges include:

- Plastic is made from petroleum, a non-renewable resource that is environmentally damaging to extract

- Some plastics are challenging to recycle for a variety of reasons (we’ll save that for another Deep Dive!)

- Many plastics are destined for landfills, where they sit for hundreds of years, or incinerators, where they are burned and release toxic fumes

- Some plastics have a tendency to wind up in the environment, especially consumer-destined single-use plastics, and if they do, they take hundreds of years to degrade

- As plastics sit in the environment, they cause harm to wildlife and often emit microplastics

These, among other problems, are challenges that packaging companies are trying to address. While some packaging applications lend themselves to changes in materials, like switching from paper to plastic, other applications are harder to replace with something that…isn’t plastic. One way the packaging industry has tried to address this is through the use of “bioplastics,” a term which is usually shorthand for plastics made from renewable feedstocks.

In particular, there has been a movement toward bioplastics that are designed to decompose to avoid some of the harms mentioned above. The idea is that if someone can design plastic that is no longer made of petroleum and that is also designed to disappear, we’ve solved the plastics problem. Right?

As with everything sustainability-related, the reality is nuanced and there are ethical gray areas. First, let’s dive into what the term “bioplastics” means.

The complex landscape of bioplastics

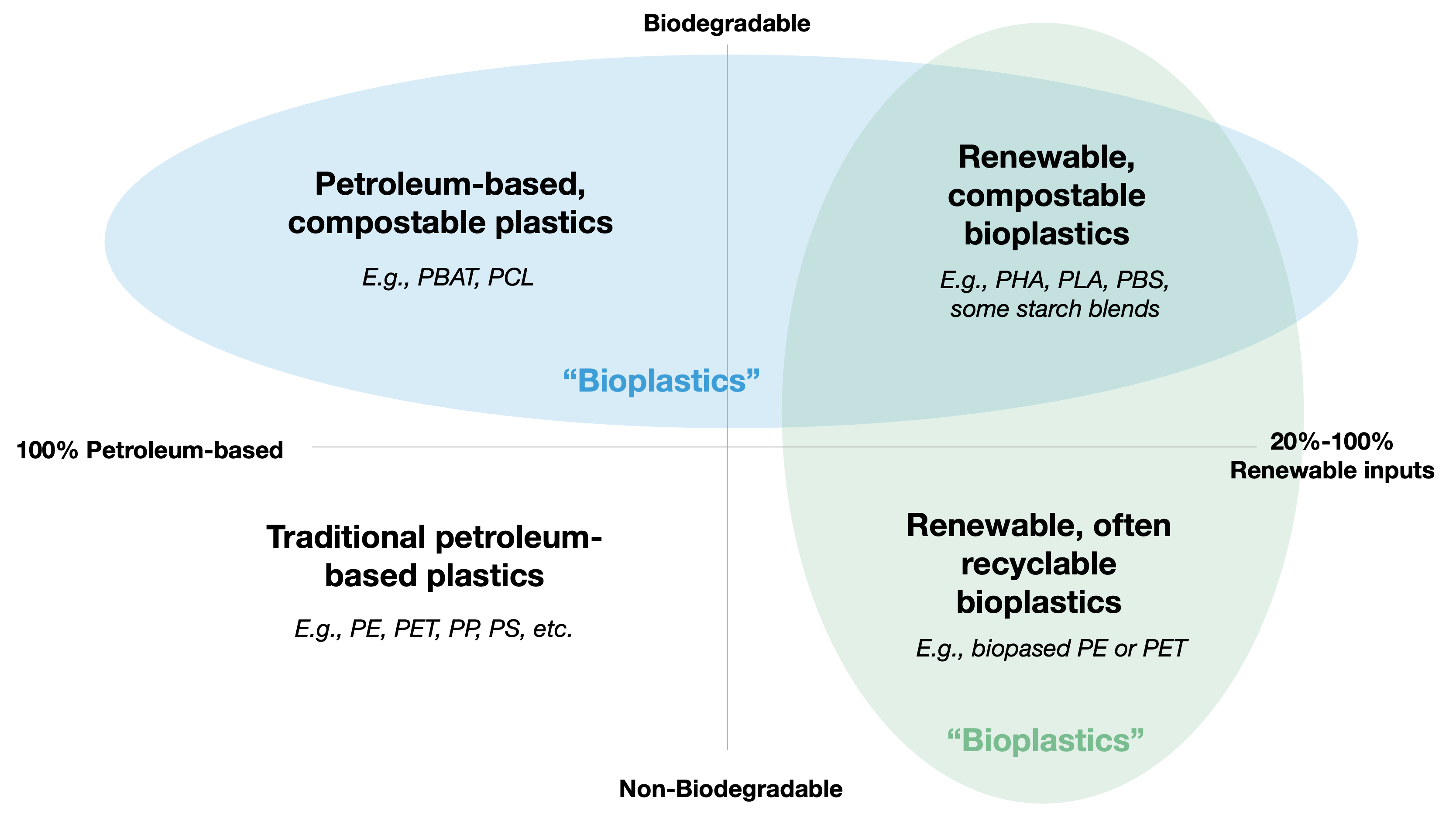

- The challenging thing about the word “bioplastics” is that it’s often used to describe two different, but ultimately unrelated, traits of some of these special plastics:

Renewable feedstocks – you may see the word “bioplastic” used to describe a plastic made partially or entirely from plants. The feedstock is most commonly a plant such as sugarcane or corn. - Biodegradability– sometimes “bioplastic” is meant to refer to a plastic’s ability to break down into elements found in nature, typically referred to as either “biodegradability” or its stricter cousin, “compostability.”

These are the two dimensions we use to understand what exactly is meant by a “bioplastic.”

As you can see from the graph above, “bioplastics” may refer to plastics that are both made from renewable inputs and that are also biodegradable. However, the term may also be referring to plastics that are made from renewable feedstocks but are not designed to be biodegradable, and it can also refer to plastics that are made from petroleum but are designed to be compostable. These two dimensions can cause confusion, so we encourage our salesforce, suppliers, and customers to be more specific than “bioplastics.”

Let’s look at each of the three quadrants highlighted above in turn to discuss those plastics’ traits. We can examine them on three dimensions: structure, formulation, and end-of-life.

Renewable, biodegradable/compostable bioplastics

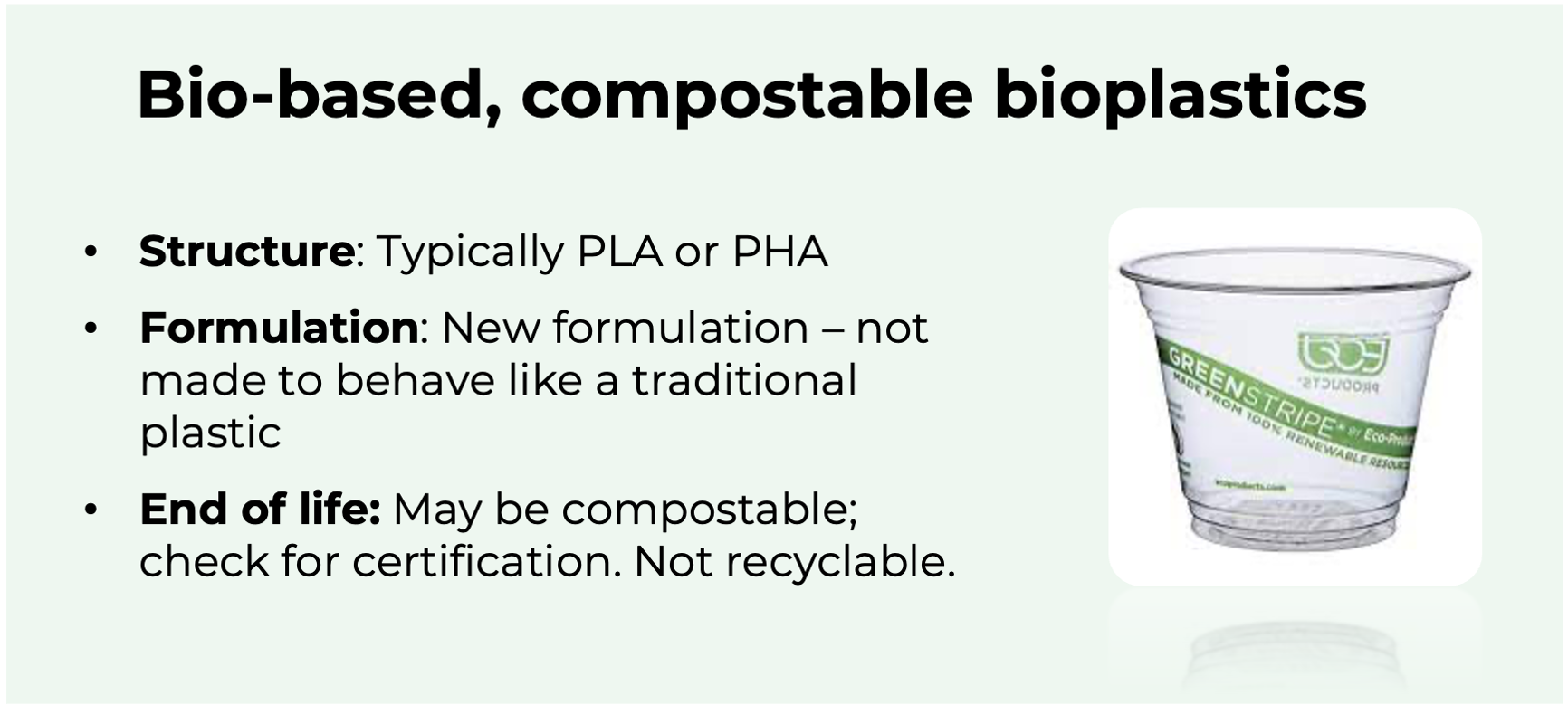

The most commonly thought of types of plastic in this category come from polylactic acid (PLA), which is often made of corn, or polyhydroxyalkanoate (PHA), which is a polymer produced by bacteria. This formulation likely feels like traditional plastic to the naked eye, but it is ultimately not designed to behave like traditional plastic so that it can achieve biodegradability or compostability. If you’ve used compostable cups like the one pictured above, or maybe compostable cutlery, you’ve interacted with this kind of plastic.

The most commonly thought of types of plastic in this category come from polylactic acid (PLA), which is often made of corn, or polyhydroxyalkanoate (PHA), which is a polymer produced by bacteria. This formulation likely feels like traditional plastic to the naked eye, but it is ultimately not designed to behave like traditional plastic so that it can achieve biodegradability or compostability. If you’ve used compostable cups like the one pictured above, or maybe compostable cutlery, you’ve interacted with this kind of plastic.

Typically, these plastics are designed to be compostable and have certifications instructing consumers to compost through industrial composting.

Less commonly, these plastics may be able to go into home compost. (More on compostability certifications in Part 2 of this series!)

Renewable, often recyclable bioplastics

This plastic is designed to be “dropped in” with existing traditional plastic, and as such, it behaves like traditional plastic too.

You’ve probably seen this kind of plastic in some beverage bottles that advertise having plant-based plastic in them. These are still using PET but are just using a mixture of petroleum-based and plant-based PET.

You’ve probably seen this kind of plastic in some beverage bottles that advertise having plant-based plastic in them. These are still using PET but are just using a mixture of petroleum-based and plant-based PET.

Since the plastic is designed to behave just like traditional plastic, bioplastics of this kind can be recycled to the same extent their traditional counterparts are. In other words, a bottle with some plant-based PET would be as recyclable as one with entirely petroleum-based PET.

Petroleum-based, compostable bioplastics

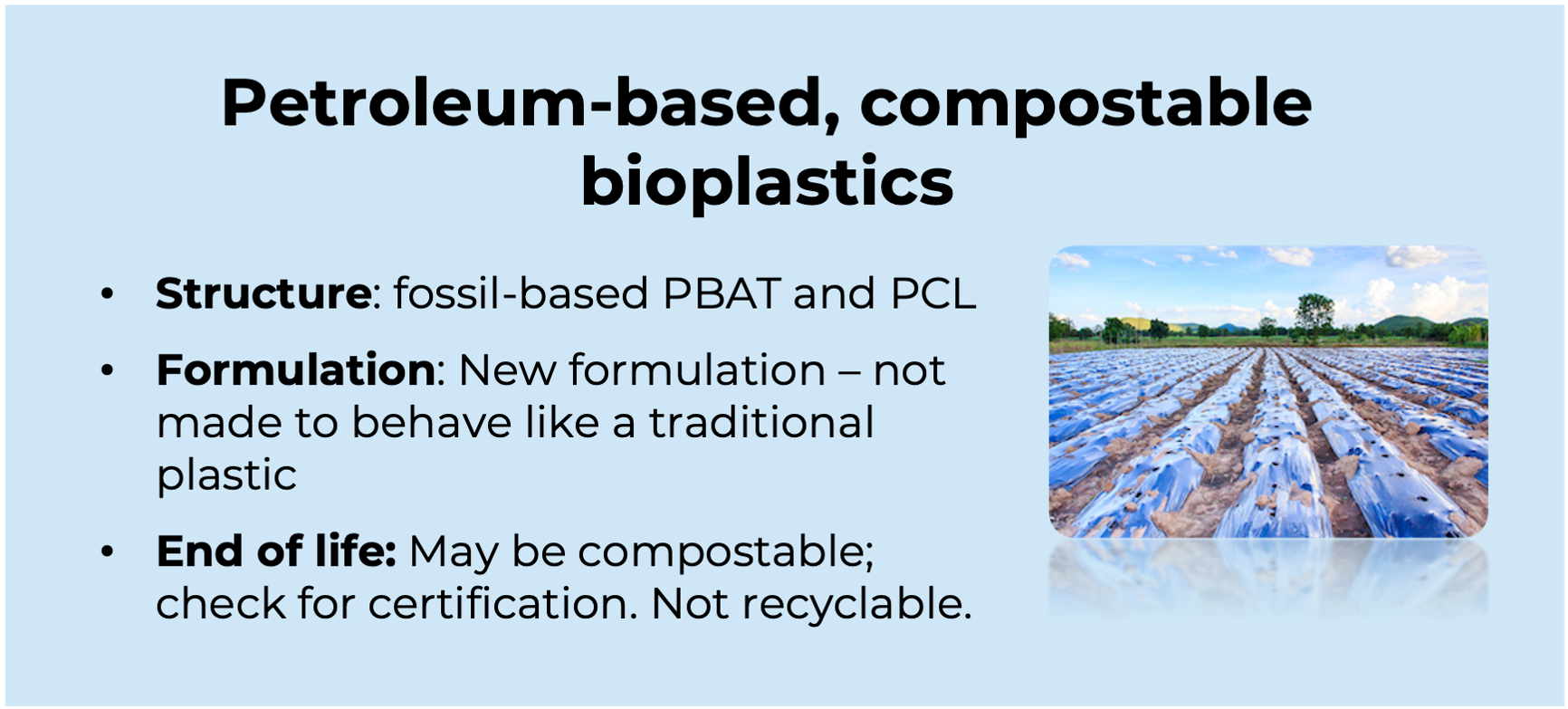

Lastly, “bioplastics” may be referring to materials polybutyrate (PBAT) and polycaprolactone (PCL).

Lastly, “bioplastics” may be referring to materials polybutyrate (PBAT) and polycaprolactone (PCL).

These structures are fossil fuel-based but are designed to be compostable. Similar to PLA and PHA, PBAT and PCL are fundamentally different formulations for plastics so are not designed to be recyclable.

Some people wonder why they should bother using a fossil fuel-based compostable plastic when bio-based compostable plastics are available. PBAT can have some advantages compared to PLA or PHA.

For example, PBAT may have better heat resistance or provide barrier properties that are challenging for PLA or PHA. Keep in mind that some compostable plastics are composed of both bio-based and petroleum-based polymers.

Do bioplastics have a lower environmental footprint than regular plastics?

More complicated sustainability questions! The short answer is: it depends…on a lot of things. How is the feedstock for the bioplastic grown? What does the manufacturing and converting process look like? What happens to it at the end of its life? Are we most concerned about bioplastics’ greenhouse gas (GHG) emissions, their water use, their ecotoxicity, etc.?

While there are many variables to consider in assessing the footprint of bioplastics, in theory, bioplastics should be able to have lower emissions than petroleum-based plastics since they absorb carbon from the atmosphere rather than pulling stored carbon (in the form of fossil fuels) out of the ground. Many life cycle assessments (LCAs) have found that bioplastics have lower global warming potential (GWP) than petro-plastics, but this is not automatically true just because a plastic comes from a bio-based feedstock.

Which type of bioplastic is best?

As with any packaging- or sustainability-related question, the answer is that it depends! In some applications, the designer may be trying to optimize for home-compostability rather than industrial, so they might choose a formulation that allows for that. In other cases, the designer may want certain barrier properties that one structure provides better than the others.

When assessing the sustainability of a bioplastic, our concern is less about what exactly the polymer structure is and more about questions like actual compostability, sourcing, feedstocks, end-of-life (EOL) outcomes, and packaging applications.

Other sustainability considerations and concerns for bioplastics

Many an article has heralded bioplastics as the silver bullet to solve the plastic waste crisis, but every substrate carries some inherent sustainability risks and questions. As we start to see more bioplastics proliferate in the packaging industry, we’ve been encouraging our suppliers and customers to consider some of the following impacts.

Sourcing: Agricultural Methods

Bio-based plastics can come from a variety of feedstocks from corn to sugarcane to seaweed. There is not a perfect feedstock, and many sustainability advocates have raised the alarm that sourcing plastics from commodity crops like corn could perpetuate heavily industrialized monocultural agricultural practices that are harmful to the environment. While there is no easy answer to how crops for bioplastics should be grown to be considered “sustainable agriculture,” we like to ask suppliers of bio-based plastics if they have insight into how these crops are grown.

Sourcing: Land Use Changes

Additionally, one of the sourcing concerns for bio-based plastics surrounds whether arable land is being converted to use for growing crops for bioplastics rather than food. According to the World Wildlife Fund (WWF), about 0.016% of the total global agricultural area is being used to grow bioplastics. This is quite small for now, but a growth in bioplastics production will inevitably be accompanied by more land area being needed. It will be important that the sustainable packaging community keep in mind the total amount of land being used for bioplastic production as its use rises. The worst-case scenario that we will also need to monitor for is if forests are being destroyed to make room for land to grow bioplastics.

Some types of feedstocks such as seaweed can help alleviate concerns about land use change. In ideal cases, crops (including ones like seaweed) are grown in a regenerative fashion to create healthy habitats and foster biodiversity while they’re in the process of being grown. In our opinion, crops grown with regenerative agriculture, as well as feedstocks that come from waste products, represent some of the best-case scenarios for bioplastic production.

Undesirable End-of-Life Outcomes: Littering

Some sustainability advocates have raised concerns about the impact of bioplastics if they are littered. Many consumers see on-pack messaging about “biodegradable” or compostable packaging and think that this means that it will disappear if put into land or water. As we’ll discuss in Part 2 of this series, biodegradable or compostable plastic typically needs very specific conditions to degrade.

Most bioplastics are not designed to disintegrate on the side of a highway or in bodies of water. In fact, most bioplastics behave like normal plastics in these environments, and so we often see similar effects on wildlife when bioplastics are littered. For instance, a drinking straw made from a bioplastic can have similarly detrimental effects on marine animals as straws made from traditional plastic. It is just as important that we keep bioplastics out of the environment as it is that we keep petro-plastics out.

Undesirable End-of-Life Outcomes: Recycling

We discussed that some bioplastics with a “drop-in” formulation, like plant-based PET, can be recycled alongside their petro-based counterparts. However, other compostable bioplastics like PLA, PHA, and PBAT cannot be recycled, and they in fact will have detrimental effects on the recycling stream if they are. Many experts in the packaging waste space are concerned that consumers don’t understand the difference between composting and recycling. Consumers may see “green” marketing on the package and see that as a hint to recycle it. Recyclers have already raised the alarm that they are seeing increased contamination in materials recovery facilities (MRFs) from compostable plastics. As bioplastics become more common, it will be critical that we properly educate consumers on the importance of differentiating compost from recycling.

Undesirable End-of-Life Outcomes: Landfills

There is also a misconception among many consumers that compostable or biodegradable plastics will also degrade in a landfill and are a more sustainable choice. However, landfill chemistry makes this issue much less straightforward. Depending on the conditions in a given landfill such as microbe and enzyme activity, some materials may begin to degrade in landfills; others will not. From a GHG perspective, though, it is actually undesirable for items to break down in landfills. This is because landfills are largely anaerobic environments, and when organic materials break down in anaerobic environments, they produce methane. Methane is a potent GHG about 20 to 80 times as powerful as carbon dioxide, and one of the main concerns about landfills is that they are the third-largest source of man-made methane emissions. Counterintuitive as it may seem, from a GHG perspective, we do not want materials breaking down in landfills.

As you can see from the many ways in which different end-of-life outcomes can affect the sustainability of biodegradable plastics, there is really only one ideal outcome: for them to be composted. In Part 2, we’ll tackle what composting is, how it’s different from biodegradability, and when compostable packaging is a good alternative.