The Guardian Taping System

Reduce Material Waste & Save Money

High-Performance, Automated Taping

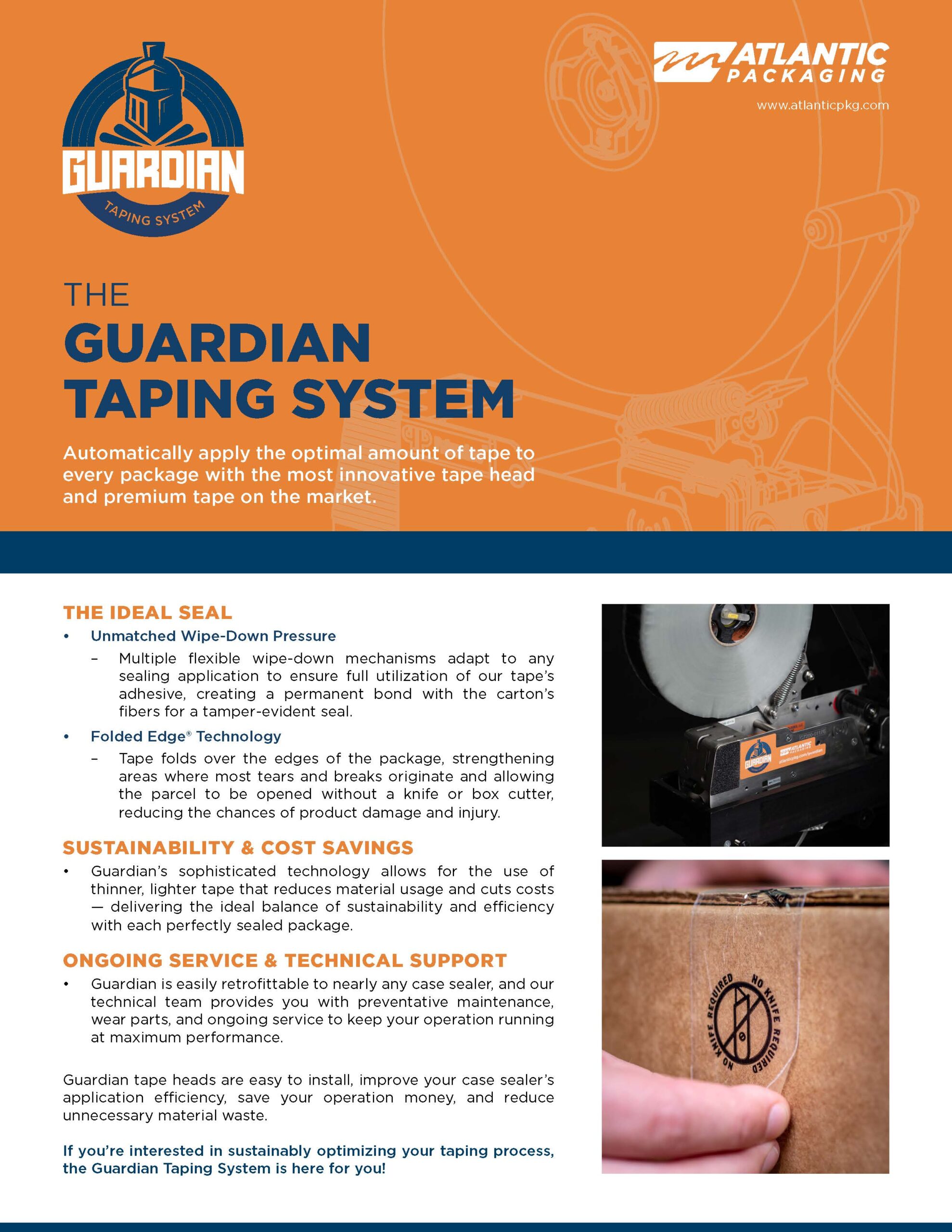

The Guardian Taping System automatically applies the optimal amount of high-quality tape to every package that comes down the production line.

REDUCE PRODUCT DAMAGE & MATERIAL USAGE

The consistent optimal application of the ideal amount of tape with extreme wipe-down pressure ensures a secure seal, increased product protection, and less overall material usage.

FOLDED EDGE® TECHNOLOGY

The program ensures that tape folds perfectly over the edges of the box. This strengthens the overall seal of the parcel, reduces the chance of nicks and tears along the tape’s seal, and allows the carton to be opened without a knife or boxcutter.

ONGOING SERVICE

Guardian is retrofittable to almost any case sealer, and we provide preventative maintenance, technical service, and part replacements for our valued partners.

The Guardian Taping System

Save time. Save money.

With the Guardian Taping System, you get an innovative, automated sealing system that puts an end to difficult tape roll changeovers that slow production, place unneeded stress on operators, and keep lines from running at peak production.

It may seem tempting to take taping and case sealing for granted. However, if you have tape that breaks, doesn’t seal properly, or doesn’t close the case correctly, you’ll have issues with production, re-working, material waste, and product protection.

Guardian provides your packaging line with a tape head that dispenses and applies the optimal amount of high-performance tape for your unique application for consistent, reliable performance.

We partnered with ShurTape to develop the Guardian Taping System to create a more efficient and sustainable taping system. This system uses hot-melt adhesive with enhanced wipe-down pressure, so you get full utilization of the tape’s adhesive for maximum product protection. It also has Folded Edge® Technology that folds the edges of the tape along the length of the carton, reducing the possibility of nicks and tears along the tape seal. This allows the carton to be opened without the use of a knife. We also provide our partners with technical service and preventive maintenance to maintain the performance of the tape heads for the long term.

We’re proud to offer such an innovative taping system to keep your packaging operation running at optimal performance.

WHAT WE OFFER

Innovative Taping Solutions

need help? Call us

(800) 722-5841

or

“We’re excited to offer a high-performance taping system for automated packaging lines that decreases downtime, reduces damage, improves productivity, and brings about gains in sustainability.”

Stewart Whitmire

VP, Sustainable Optimization