Packaging Solutions for a Healthy Planet

PACKAGING SOLUTIONS FOR A HEALTHY PLANET

Over 50% of global plastic pollution stems from packaging. New Earth Approved is our initiative to develop a catalog and collection of products, protocols and capabilities that are curbside recyclable and do not include any single-use plastic.

Our catalog is available to brands of all sizes who wish to enable more circular and sustainable shipping and packaging for their customers.

Our mission is to rid the world’s oceans, lakes, and rivers of plastic pollution.

Our Call to Action

Atlantic Packaging as it exists today is the most influential packaging company in the history of our industry. We are a critical part of this pivotal period of transformation in the history of our modern world.

Here’s how we ignite this revolution.

RECOGNIZE THE UBIQUITY OF PACKAGING

Packaging impacts nearly every person on this planet, nearly everyday. The impact of packaging materials reflects our societal values and ethics. Packaging is a potent symbol of change.

COMMIT TO SUSTAINABILITY

We make a dedicated commitment to sustainability As we shift toward environmentally conscious practices and materials, every package and every pallet load we deliver will showcase our values to the world.

RESPECT LIFE

We are demonstrating our commitment to preserving life and implementing essential environmental changes.

Innovations in Sustainability

Bringing sustainable packaging products & programs to market

Through groundbreaking technologies, collaborative partnerships, and an unwavering dedication to environmental stewardship, we’re forging a path toward a better future for industries and communities worldwide.

Sustainably optimize the stretch film application process for consistent load containmnet and to minimize film entering the waste stream.

This is where you’ll find a blend of innovation and expertise, guided by engineers working day-to-day with packaging applications that span a massive variety of industries and unique challenges.

Cruz Foam, derived from sustainably sourced chitin found in shrimp shells, not only diverts waste from landfills but also replaces conventional packaging foam, thereby contributing to a circular economy.

Cruz Foam, derived from sustainably sourced chitin found in shrimp shells, not only diverts waste from landfills but also replaces conventional packaging foam, thereby contributing to a circular economy.

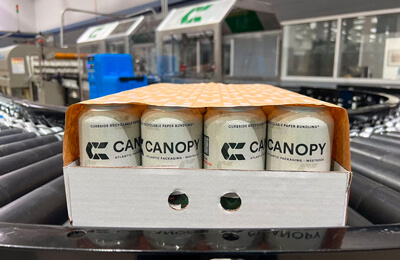

With Canopy™ Wrap, you can transition to fully curbside-recyclable bundling for bottles and cans by replacing traditional shrink film with a recyclable fiber-wrap solution.

With Canopy™ Wrap, you can transition to fully curbside-recyclable bundling for bottles and cans by replacing traditional shrink film with a recyclable fiber-wrap solution.

Fishbone beverage carriers are curbside-recyclable paperboard carriers designed for your beverage packaging needs, offering eco-friendly materials, ample branding space, and efficient application through equipment options.

Fishbone beverage carriers are curbside-recyclable paperboard carriers designed for your beverage packaging needs, offering eco-friendly materials, ample branding space, and efficient application through equipment options.

Find sustainable, paper-based cushioning and void fill protective packaging systems for businesses large and small to replace single-use plastic air pillows and bubble wrap.

S3 Surfboard Shipping

The S3 System provides an innovative and sustainable surfboard shipping alternative with fiber-based SUS-RAP packaging that is curbside recyclable, offering efficient shipping, preparation, and reusability.

The S3 System provides an innovative and sustainable surfboard shipping alternative with fiber-based SUS-RAP packaging that is curbside recyclable, offering efficient shipping, preparation, and reusability.

FibreStrap is a sustainable paper cable tie, designed to replace current plastic zip tie solutions for bundling, securing, and attaching in any industry.

FibreStrap is a sustainable paper cable tie, designed to replace current plastic zip tie solutions for bundling, securing, and attaching in any industry.

Sway’s regenerative seaweed packaging replicates the essential performance characteristics of plastic packaging and integrates with existing infrastructure, allowing for scale and competitive pricing.

Sway’s regenerative seaweed packaging replicates the essential performance characteristics of plastic packaging and integrates with existing infrastructure, allowing for scale and competitive pricing.

ATLANTIC’S OPERATIONAL SUSTAINABILITY

OVERALL BUSINESS STRATEGY & DISCLOSURES

CDP

Atlantic is committed to a sustainability and climate action program that includes disclosure, transparency, and a willingness to be evaluated from any interested party. In 2018, we first participated in the annual survey from the Carbon Disclosure Project, now CDP, and in 2023, we became the first packaging company to earn an A rating. In 2025, we received a B rating, and we remain committed to transparent reporting and continuous progress on climate action.

SCIENCE-BASED TARGETS

The Science Based Targets initiative (SBTi) represents the highest standard for climate action by helping companies create climate goals in line with the Paris Agreement. Atlantic is the first packaging company in North America to set a net-zero science-based target (SBT).

SPC is a membership-based collaborative that believes in the power of industry to make packaging more sustainable. As the leading voice on sustainable packaging, they are passionate about creating packaging that is good for people and good for the environment.

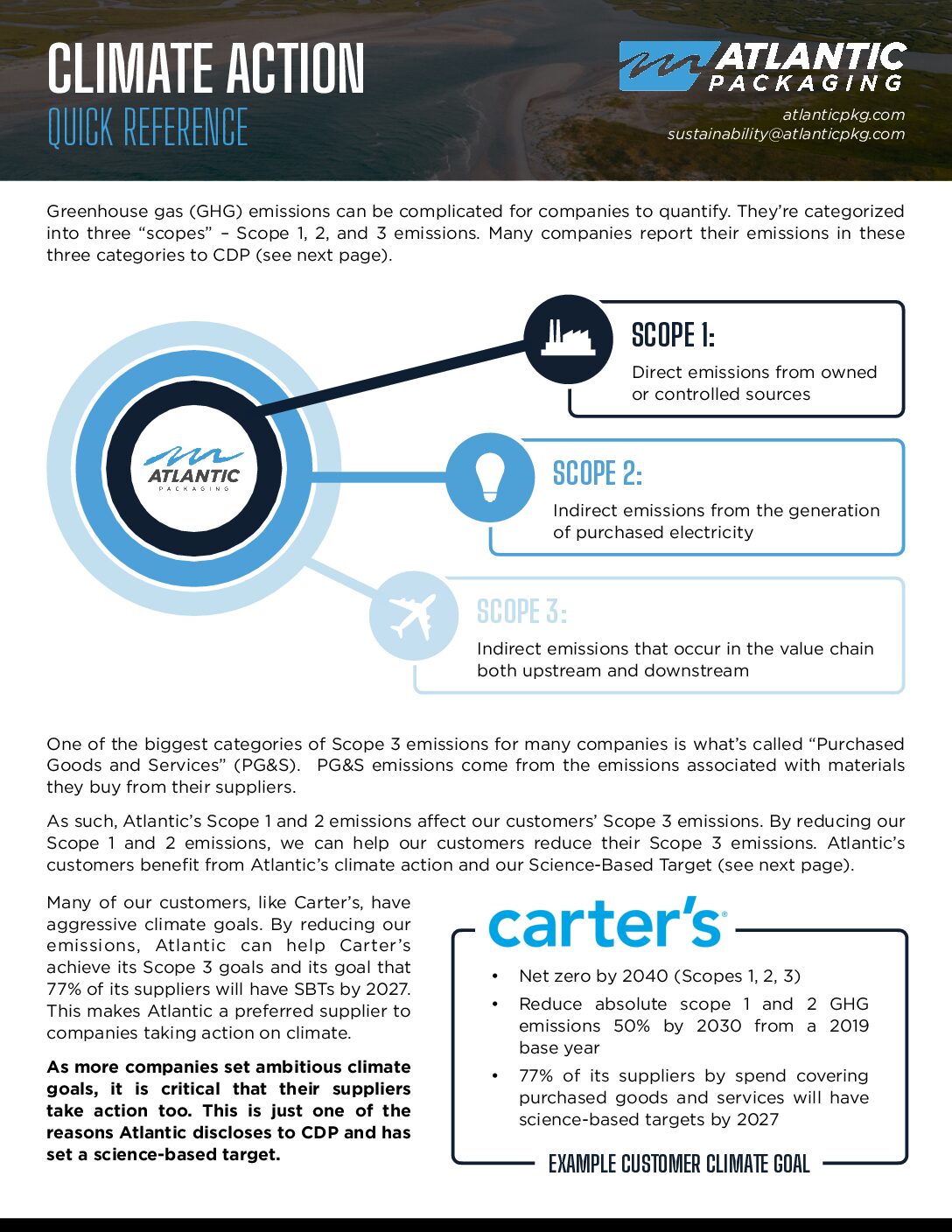

SCOPE 1, 2 & 3 CARBON EMISSIONS

SCOPE 1

- Transition to electric forklifts 70% complete

- Deposit on 10 Tesla semi trucks made in 2021

- Auditing facilities’ boilers for reduction opportunities

SCOPE 2

- Energy efficiency initiatives completed 2019

- On-site solar installed on 3 buildings

- Conversations started for VPPA in 2022

SCOPE 3

- Climate education programming for suppliers (reduce Purchased Goods & Services)

- Facility zero-waste certifications – 4 completed; 2 more per year

- Assessing the end-of-life of sold products

Take a Deep Dive Into Sustainable Packaging

Read and share our insights and articles on sustainability in packaging.

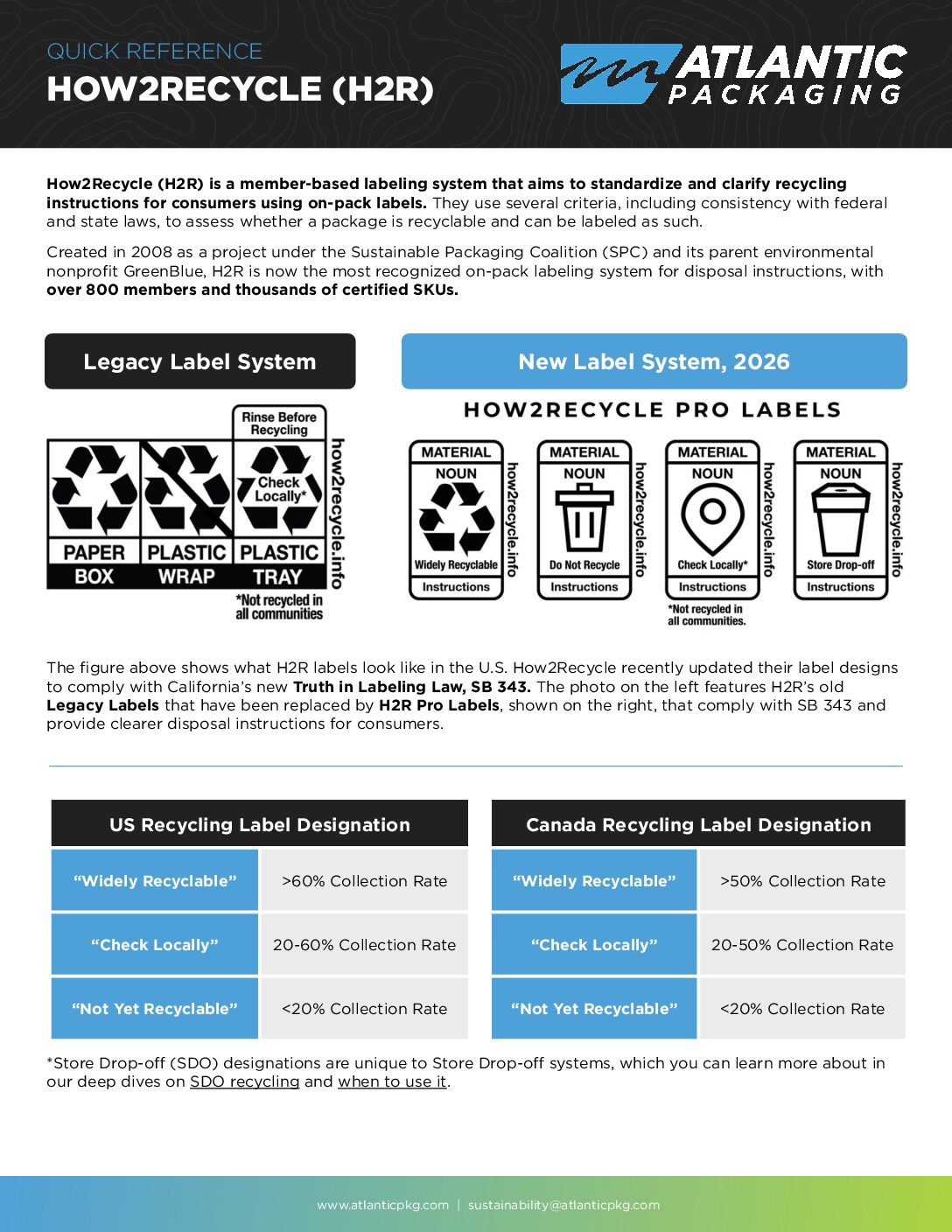

DEEP DIVE: HOW2RECYCLE AND RECYCLE LABELING EXPLAINED

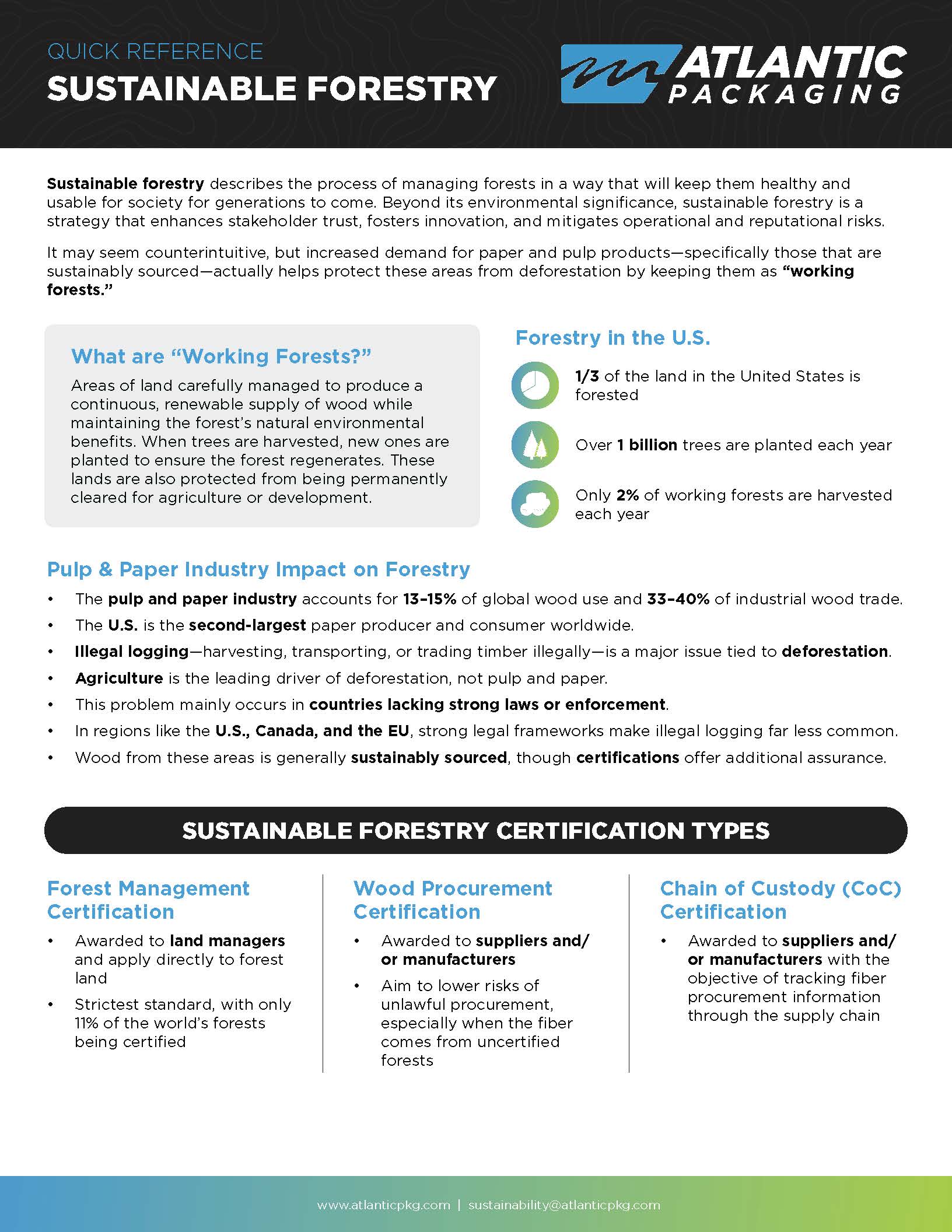

DEEP DIVE: SUSTAINABLE FORESTRY FOR PULP AND PAPER PACKAGING, EXPLAINED

DEEP DIVE: WHEN TO USE STORE DROP-OFF RECYCLABLE MATERIALS

DEEP DIVE: WHAT IS STORE DROP-OFF RECYCLING?

DEEP DIVE: WHAT IS STORE DROP-OFF RECYCLING?

DEEP DIVE: SORTING RECYCLABLES AT A MODERN MRF

DEEP DIVE: SORTING RECYCLABLES AT A MODERN MRF

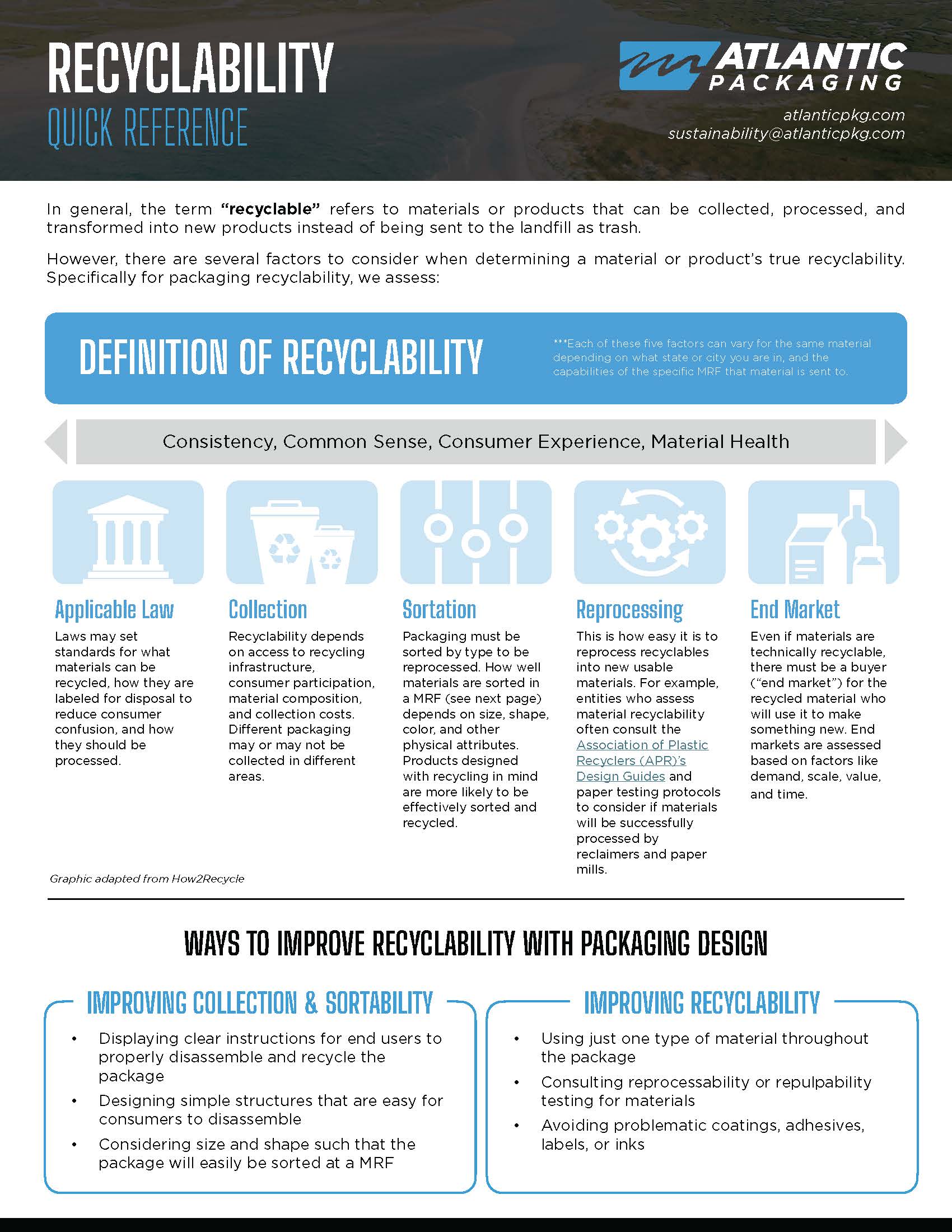

DEEP DIVE: WHAT DOES “RECYCLABLE” MEAN?

DEEP DIVE: WHAT DOES “RECYCLABLE” MEAN?

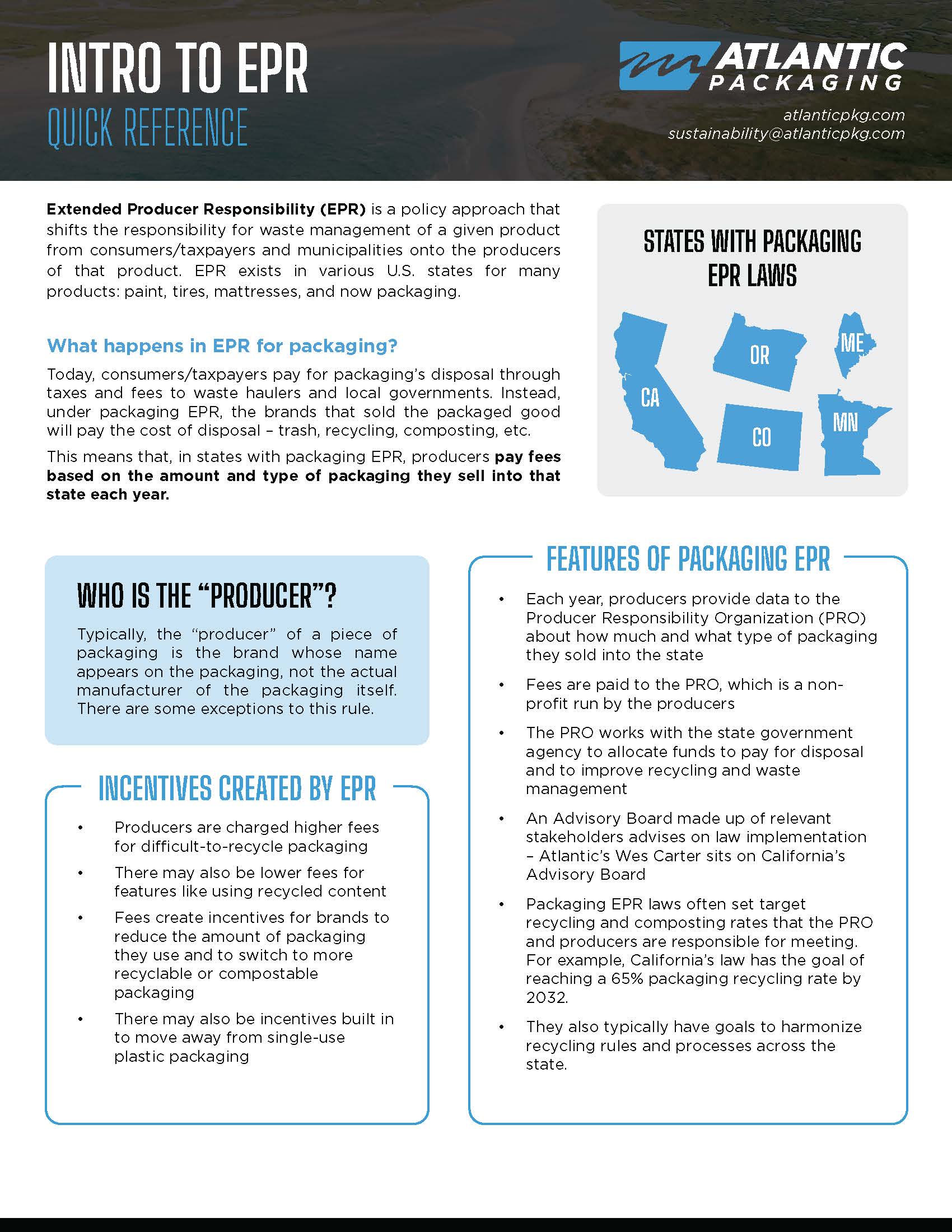

DEEP DIVE: EXTENDED PRODUCER RESPONSIBILITY (EPR) FOR PACKAGING, EXPLAINED

DEEP DIVE: PCR IN SUSTAINABLE PACKAGING

DEEP DIVE: BEST USES OF COMPOSTABLE PACKAGING

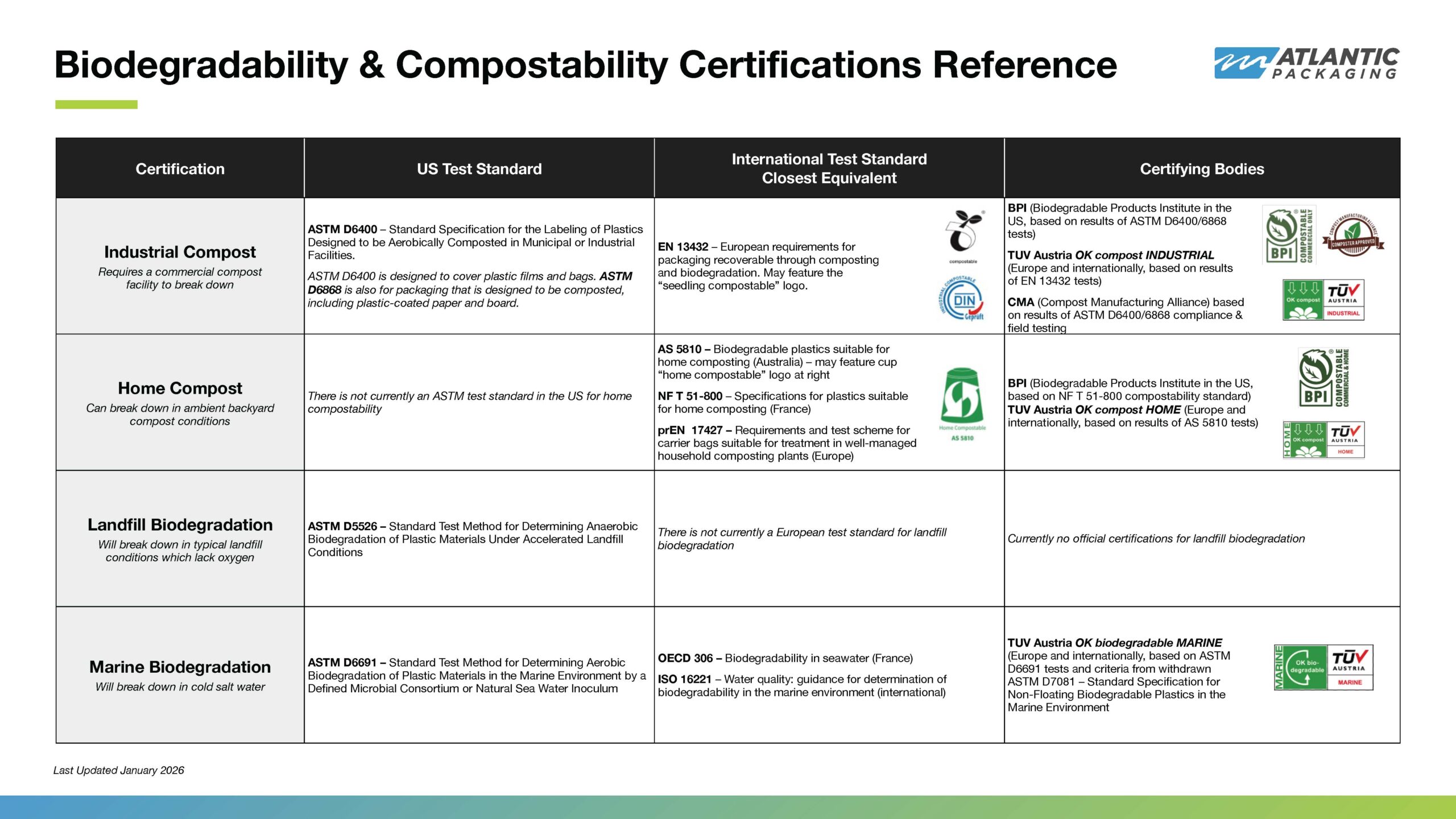

DEEP DIVE: COMPOSTING, COMPOSTABILITY, AND CERTIFICATIONS

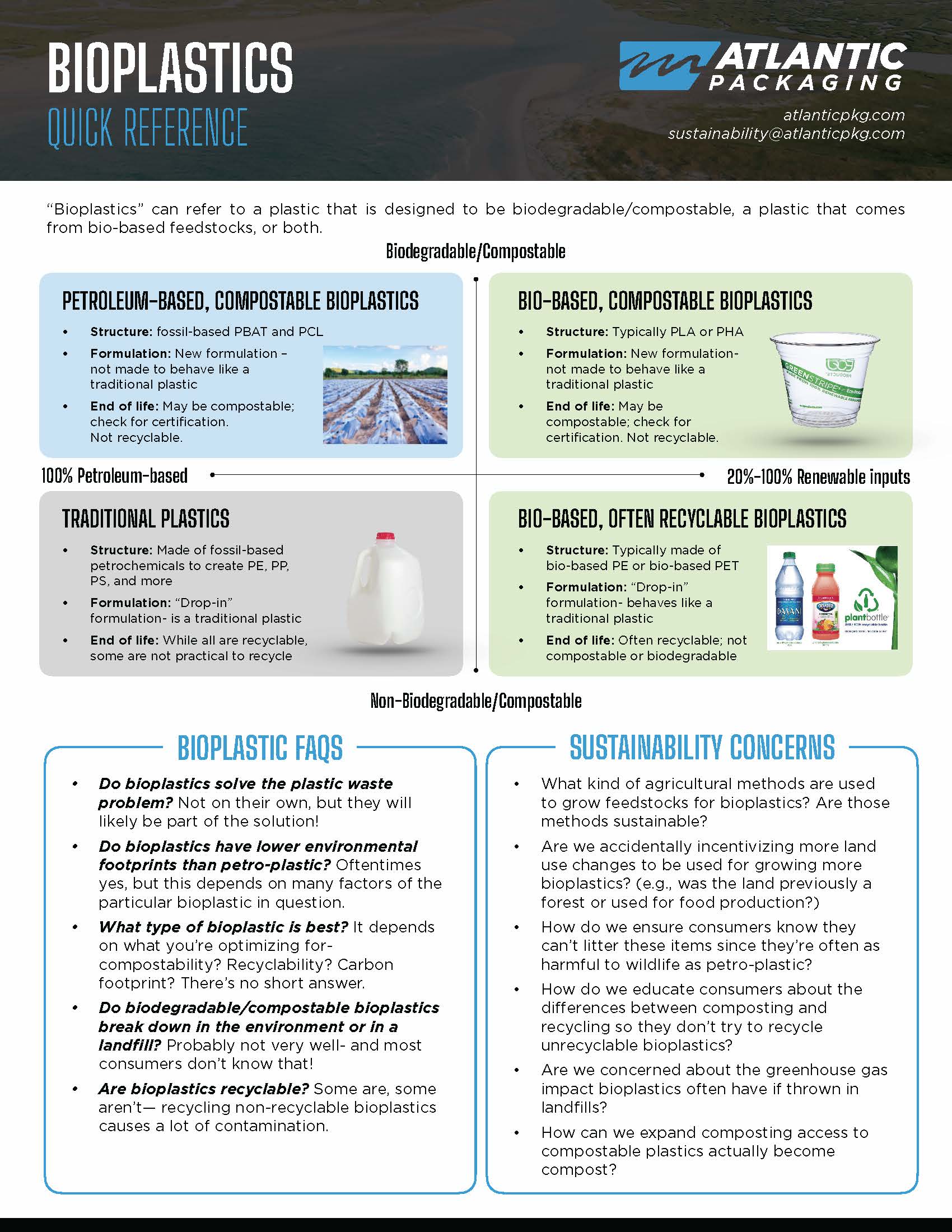

DEEP DIVE: THE BIOPLASTICS LANDSCAPE

DEEP DIVE: WHAT ARE SCIENCE-BASED TARGETS?

DEEP DIVE: WHAT IS CDP?

More Resources

Download our whitepapers and resources that explore different ideas, trends, and recommendations for sustainable packaging.

“It’s not an exaggeration to say that we’re in a revolutionary time for sustainability and a movement towards a circular materials economy. More than ever, we need businesses to dive wholeheartedly into innovating, and Atlantic’s at the forefront of a pivotal shift towards materials that are healthier for people and planet.”

Caroline DeLoach

Sustainability Director, Atlantic Packaging

need help? Call us

(800) 722-5841

or

“Our customers have well-defined, measurable sustainability goals and, as their partner in packaging, we’re committed to helping them achieve these goals. Along the way, we also help them develop strategies that improve their sustainability in new ways.”

Wes Carter

President, Atlantic Packaging