Stretch Wrapping

Stretch Film & Equipment

Prevent Product Damage Through Optimal Load Containment

Stretch film prevents costly product damage and is a crucial component of B2B logistics.

STRETCH EQUIPMENT

True cost savings can only be achieved when you match high-performance films and optimized equipment. Just like your car, there are parts on your wrapper that wear out and need to be replaced in order to operate at maximum efficiency.

STRETCH FILM

Stretch Film is not just about getting a pallet of goods from point A to point B. Stretch Film is about chemistry, it’s about film formulations that match specific customer applications. It’s about optimization.

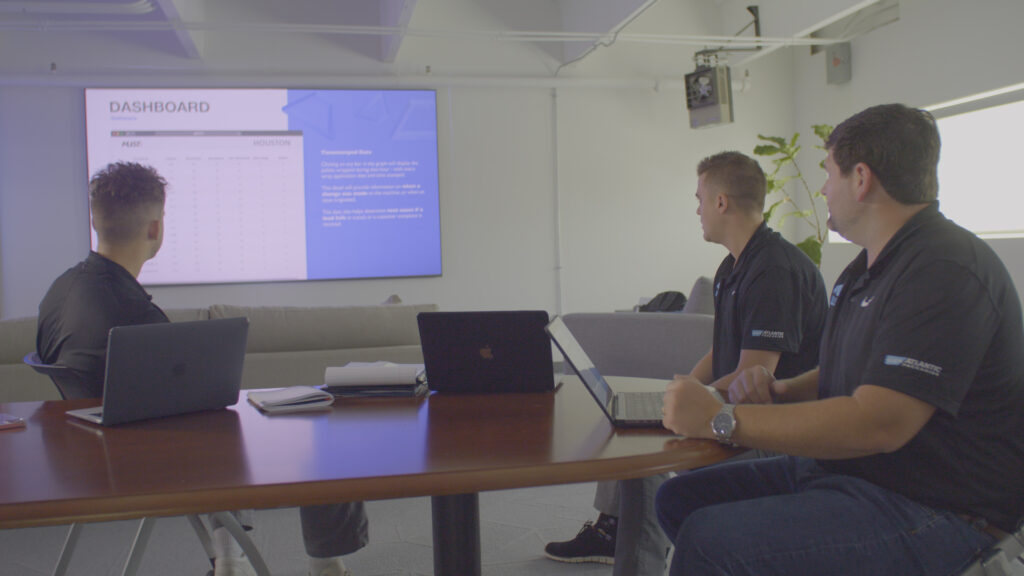

OUR TEAM

Our material specialists help you find the ideal packaging for your unique product. We curate packaging programs specific to your business needs with superior customer service and care to create long-term partnerships.

FILM LAB

Atlantic is committed to delivering data-driven results for our customers. Our state-of-the-art Film Lab facility further differentiates Atlantic’s position in the marketplace.

TESTING & MONITORING

Anything that can be measured can be optimized. We create and test wrap patterns for your specific applications and then monitor them for consistent load containmnet with minimal material usage.

AUDIT

Every stretch wrap project begins with an audit of the current process, film, equipment, and application. We want to understand your goals when it comes to stretch wrapping.

Stretch Wrapping Videos

Sub Heading

Sub Heading

Sub Heading

Sub Heading

Sub Heading

Sub Heading

Sub Heading

Sub Heading

Sub Heading

Sub Heading

Sub Heading

Sub Heading

STRETCH WRAPPING THAT WORKS

Atlantic embraces a holistic approach to stretch packaging. Our process of choosing a stretch film for a customer starts with an audit of their current operations to understand their product, needs, and goals relating to stretch wrapping. Our specialists source a film unique to your specific application and train equipment operators on the benchmark settings for consistent load containment and stretch film results.

Beyond the sale of equipment and film, we help monitor the stretch film operation to know that benchmarks are met with each application to maximize load containment and product protection while minimizing material usage and environmental impact.

We want to set you up for success with your stretch packaging and create meaningful long-term partnerships to ensure ongoing success.

Learn more about our end-to-end approach to stretch wrapping with the MUST Stretch Management System.

WHAT WE OFFER

A Research-Based Approach to Stretch Film

need help? Call us

(800) 722-5841

or

Featured Partners

“The value Atlantic brings in stretch wrapping is performance, optimization, and consistency. Our program marries high-performance films stretched with optimized wrappers, standardized wrap patterns, and equipment settings to create well wrapped loads and save substantial dollars in annual spend.”

Stewart Whitmire

VP Sales, Atlantic Packaging