Sway Seaweed Packaging

Flexible film made with a regenerative resource

Materials that replenish the planet

FROM SEA TO SOIL

Created with Sway’s TPSea™ technology: a first-of-its-kind resin made entirely from seaweed and plants. It can be blended with other compostable polymers through various manufacturing techniques to create a wide variety of end products.

OPTIMIZED FOR EXISTING INFRASTUCTURE

Replicates the essential performance characteristics of plastic packaging and seamlessly integrates with existing infrastructure.

PLASTIC FILM REPLACEMENT

Replaces traditional LDPE plastic with a translucent, durable, moisture-resistant alternative that is made with biobased and responsibly sourced materials.

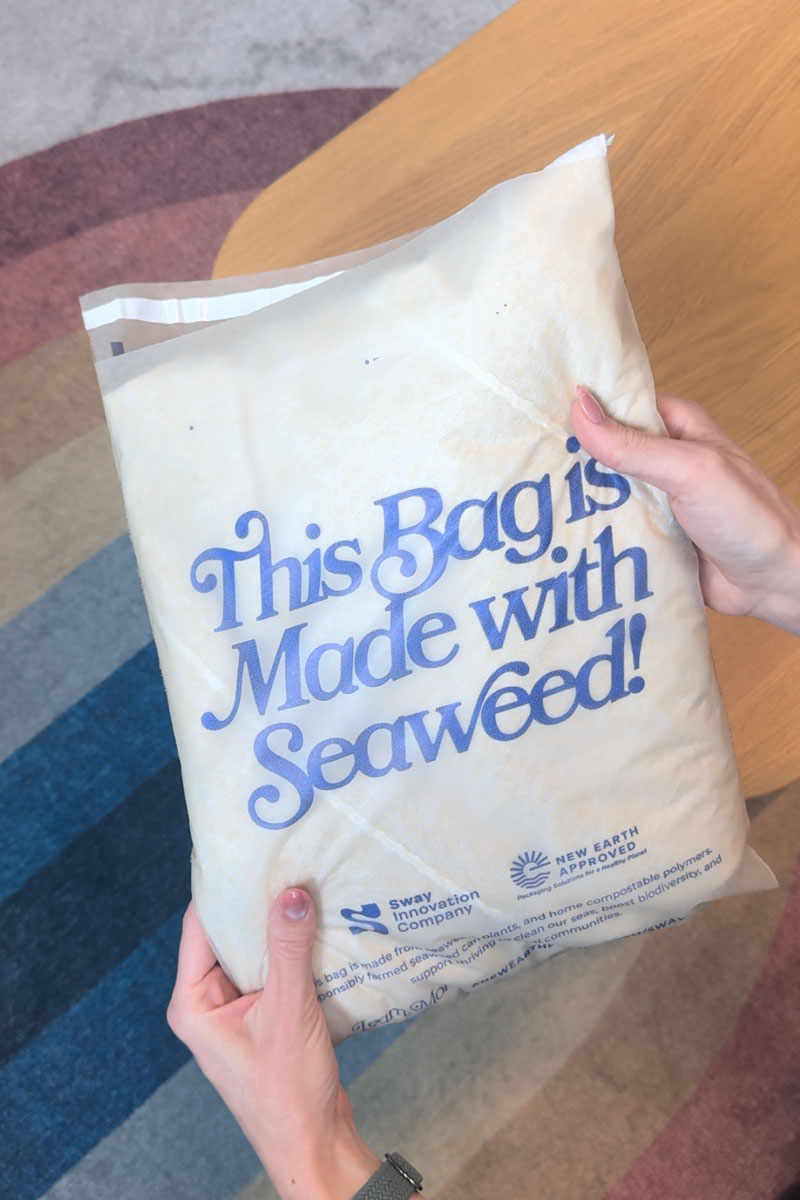

SWAY POLYBAG

Made with seaweed, plants, and compostable polymers

This polybag solution is made with a planet-replenishing resource: seaweed. Sway Polybags are durable, protective, lightweight, and designed to protect goods in transit from your factories to your customers.

Currently, the Sway Polybag is best suited to package dry items like apparel, outdoor gear, personal care, accessories, and home goods.

And now, we’re so excited to share that Sway TPSea Flex, the material used to make the Sway Polybag, was named a TIME Best Invention of 2025! TIME’s recognition is more than a trophy. TIME’s recognition is more than a trophy. It’s a signal that next-generation, circular materials are ready to replace conventional plastics at scale.

Are you searching for an eco-friendly option to replace thin-film plastic?

Sway’s circular seaweed-based packaging replicates the essential performance characteristics of plastic packaging, while integrating seamlessly with existing infrastructure – allowing for scale and competitive pricing.

Sway’s materials aim to replenish life from sea to soil. They partner with a global network of ocean farms, from commercial suppliers to small-scale farmers, supporting coastal communities and healthy ecosystems.

WHAT WE OFFER

A Sustainable Alternative to Thin Film Plastic

OUR FIRST ADOPTER: CHRIS BENCHETLER

Read the Case Study here: UNPACKED: Artist Chris Benchetler with Sway Seaweed Packaging

BUILDING A FUTURE TOGETHER

This is just the beginning!

Sway is a material innovation company on a mission to bring materials made from abundant, planet-replenishing resources into the mainstream. Their first product – the Sway Polybag – is an entirely new technology that Atlantic Packaging has adopted to showcase a next-generation solution that could viably replace the 180 billion polybags used annually in the fashion industry alone. While that is an enormous amount of plastic to offset by itself, this packaging format is just the first step in a much more ambitious vision.

Together, Sway and Atlantic Packaging are working toward a myriad of solutions to reduce and replace plastics. From flexibles to rigids, food-grade to waterproof, we are actively exploring the technical boundaries of what Sway technology can do, now and in the future. Right now, we are focusing on scaling this technology for a relatively straightforward application: polybags. But we’re eager to develop Sway films that are food-grade, because we agree that the most promising applications for compostable packaging are in food-contact items. It’s going to take refining our first products like Sway Polybags to get us to a place where we can really bring food-contact films to life.

It’s also going to take radical collaboration with experts across policy, the compost industry, and science to design solutions that leave a legacy, not waste. Unlike many compostable packaging solutions on the market today, we believe that Sway products are themselves beneficial to compost, enriching it with nutrients not found in other biomaterials. That said, we know that the compost landscape is complex, and we’re committed to working with composters to increase acceptance of regenerative materials like ours.

By scaling next-generation materials, we can transform entire supply chains, reducing demand for harmful petrochemicals while actively healing natural systems.

“Atlantic’s partnership with Sway presents an incredibly exciting opportunity to introduce the market to a thin film made with regenerative seaweed as an alternative to ubiquitous plastic film.”

Don Meek

Director, A New Earth Project