Also check out our Sustainability Terms Glossary, where we’ll add key terms from each of our Deep Dives over time. Bookmark this page for future reference!

In Part 1 of this series, we discussed how the term “bioplastics” can refer to many different things, including (but not limited to) biodegradable or compostable plastics. But what do “biodegradable” and “compostable” mean? What happens in a composting environment at home versus a commercial composting facility? In Part 3 of this series, we’ll cover the appropriate uses of compostable packaging.

What is composting, and how is it part of a circular economy?

Compost is a nutrient-rich, dark, crumbly material that results from the decomposition of organic matter, a process called composting. Composting is the controlled and accelerated breakdown of organic materials, such as kitchen scraps, yard waste, and other biodegradable materials (including some packaging) by microorganisms, bacteria, fungi, and other decomposers. During composting, these organisms break down the organic matter into simpler substances, releasing carbon dioxide, water, and heat in the process.

Just like we can recycle materials like plastic, paper, metal, and glass, composting represents a way to “recycle” organic material so that it doesn’t go to a landfill. You may even hear composting referred to as “organics recycling.” When we compost, we keep organic material circulating in our economy and turn it into a useful product for gardens, farms, and landscaping.

It’s critical that we keep organic material – whether it’s food, packaging made from organic material like paper or bioplastics, or lawn trimmings – out of landfills. Not only do they represent wasted material that we can’t get back; they also cause a major climate issue. In landfill conditions, organic material breaks down mostly anaerobically. When this occurs, a main byproduct is methane gas, which is an extremely potent greenhouse gas (GHG). It’s about 20 to 80 times as powerful as carbon dioxide, so keeping organic materials out of landfills is an important climate initiative. Meanwhile, in a composting environment, material mostly decomposes aerobically and produces very minimal methane.

What is the difference between “biodegradable” and “compostable”?

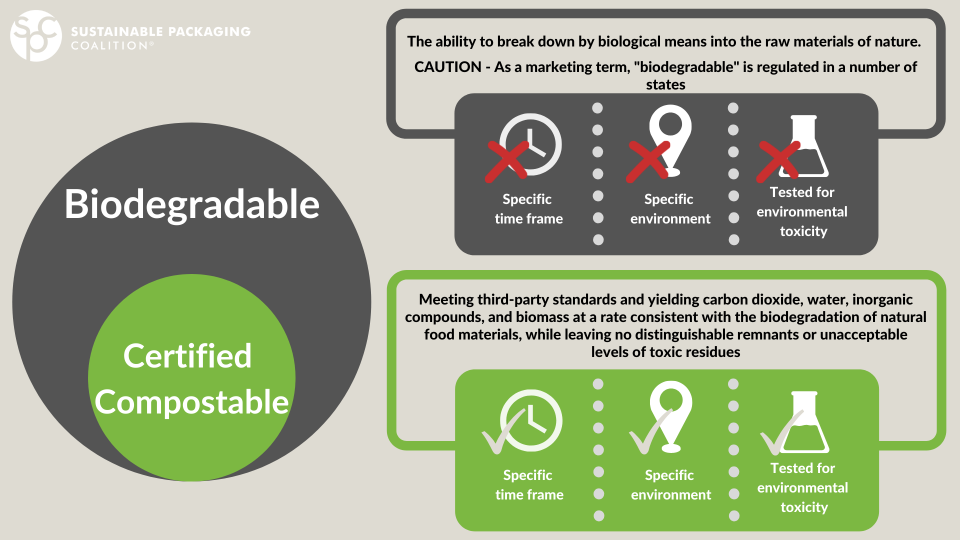

“Compostable” is a subset of the term “biodegradable.”

Materials that are biodegradable can be broken down into increasingly smaller pieces by bacteria, fungi, or microbes to be assimilated into the surrounding environment. Typically, the word “biodegradable” is used to mean that the material breaks down into innocuous products that are already found in nature. Some items are naturally biodegradable and can be useful to the earth, like food and plants. Other items can decompose but cause harm to surrounding ecosystems by releasing toxic chemicals. For example, even plastic can biodegrade because it eventually is broken down into smaller and smaller pieces that are absorbed into the Earth, but it takes an incredibly long time and releases toxins along the way. Because anything that eventually breaks down can be called biodegradable, it is often a misleading term used for greenwashing. There are not strict standards in the packaging industry about what can be called “biodegradable.”

“Compostable,” on the other hand, refers to a product or material that is biodegradable under specific, human-driven circumstances. Composting requires human intervention. During composting, microorganisms break down organic matter. Humans help by adding the water, oxygen, and organic matter necessary to promote relatively fast biodegradation. When the degradation is complete, the final product is called compost, which is a nutrient-rich organic material that can be added to soil.

Anything that is compostable is biodegradable, but not everything that is biodegradable is compostable since, as we mentioned in this guide, anything can biodegrade if given enough time.

What is “degradable” or “oxo-degradable” packaging?

In recent years, some companies have begun making additives that can be added to traditional petroleum-based plastics to help them degrade more quickly. You may see them called “degradable,” “oxo-degradable,” “photo-degradable,” or even “biodegradable.” These technologies are not making the plastics compostable. Instead, the films break down into microplastics. After much evaluation and consultation with other sustainability experts, Atlantic has taken the position that the additives currently available do not offer a salient environmental benefit and may in fact do more harm than good. This is consistent with the views of the Sustainable Packaging Coalition, WWF, Berry Plastics, Paragon, the Ellen MacArthur Foundation, and many other bodies. To read more about the issues with degradable plastics, check out our stance here.

What is home composting vs. industrial composting?

Composting can occur in two main venues: at home or at industrial facilities.

Home- or “backyard”- compostable materials are designed to break down in a typical backyard composting environment, which is usually small-scale and managed by individuals at home.

People often use a compost bin or pile that they contribute to with food scraps and yard waste, and they promote degradation by turning the pile, adding water, or even adding helpful critters like worms. There is typically some heat given off the compost pile, but it’s not at particularly high temperatures.

Since individuals are tending to small-scale compost in their backyards, the conditions in a home compost pile can vary significantly. They tend to have less maintenance than industrial composting and lower temperatures. Because of these less controlled environments with lower heat, compostable packaging materials tend to break down more slowly in home compost than in industrial settings. For this reason, a package that’s certified as “home compostable” will be designed to break down more easily and will likely be less durable than those designed to compost in industrial environments.

Meanwhile, industrial or commercial composting facilities are specialized, highly controlled composting facilities equipped to handle larger volumes of organic waste. These facilities have stricter control over temperature, moisture, and aeration, allowing for more efficient and faster decomposition of organic matter. Commercial composters often will pick up or receive materials from not only homes but restaurants and commercial facilities too. Facility operators can then sell the finished product to farmers, landscapers, and more.

Meanwhile, industrial or commercial composting facilities are specialized, highly controlled composting facilities equipped to handle larger volumes of organic waste. These facilities have stricter control over temperature, moisture, and aeration, allowing for more efficient and faster decomposition of organic matter. Commercial composters often will pick up or receive materials from not only homes but restaurants and commercial facilities too. Facility operators can then sell the finished product to farmers, landscapers, and more.

Because of the higher temperatures, controlled moisture, and strict aeration in commercial composting facilities, compostable materials that may have trouble breaking down in a home environment break down more easily. For this reason, many of the compostable packaging options you see on the market today are certified as industrially compostable but are not home compostable.

In other words, everything that is home-compostable is also industrially compostable but not the other way around.

Some services have popped up in various urban areas to collect people’s residential compost and take it to industrial facilities. In this case, even though the individual is composting in their home, the material is ultimately going to a commercial composting facility. Services like CompostNow (Atlanta, Durham, Raleigh, Charleston, Asheville, Cincinnati), CrownTown Compost (Charlotte), and Wilmington Compost Company (Wilmington) offer services like these in some of Atlantic’s main geographic areas. Other cities offer drop-off programs where residents can bring their compost to central areas like farmers markets. A few cities, like Austin, offer municipally run curbside compost pickup programs.

What are the compostable product certifications?

Packaging that is designed to be compostable should go through a certification process so that consumers can trust that the package is actually designed to break down. Certifications are also a way to help consumers understand that they should place the package in compost rather than recycling.

It’s important to understand the difference between certification bodies and test standards for compostability. Certifying bodies are the organizations that put their mark on a package. They run tests via test standards to determine whether the package is actually compostable.

The main certifying body in North America is the Biodegradable Products Institute (BPI), which uses the ASTM D6400 and ASTM D6868 test standards to assess compostability. You may have seen their logo on compostable packaging. As of this writing, BPI only certifies products for industrial compostability. In North America, there is not yet a certification for home compostability or a corresponding ASTM standard.

Meanwhile, internationally, you are likely to see the certifying body TUV Austria or the European Bioplastic “seedling” logo. TUV Austria uses the test standard EN 13432 to determine industrial compostability. For home compostability (see how they have a separate logo for composting at home), they do not use an external test standard but have their own protocol for determining home compostability.

When we are assessing compostable packaging, we look for certifications from BPI or TUV Austria. Occasionally, we are presented with a product that is not certified by BPI or TUV, so we will look for evidence that the package passes a composting test standard instead. The standard is almost always either ASTM D6400, ASTM D6868, or EN 13432. These standards mean that:

- Within 180 days, 90% of the carbon in the packaging is converted to CO2

- Within 84 days, 90% of the packaging material is able to pass through a 2mm sieve

- There is no phytotoxicity, ecotoxicity, or heavy metals in the product

One criticism of compostability certifications is that the test standards test packaging using lab conditions rather than actually testing biodegradation in the field. Groups in North America such as the Compost Manufacturing Alliance are working on better understanding real-world packaging biodegradation using field conditions. Over the next few years, we expect the certifications to evolve to give field conditions further consideration.

You can check out a summary of the composting certifications by clicking the image below, courtesy of the Sustainable Packaging Coalition (SPC).

Understanding composting and these certifications can help clarify when it makes sense from a sustainability point of view to use compostable packaging. In Part 3 of this series, we’ll dive into Atlantic’s philosophy on when it makes sense to use compostable packaging.