Packaging Equipment

Packaging Line Design, Integration & Automation

Packaging Equipment Automation and Support

We have the equipment and expertise to maximize the efficiency of your packaging line.

INTEGRATION

Our engineers and technicians design full packaging line solutions to take your product from the point of manufacture to its final destination safely and securely.

PROJECT MANAGEMENT

Our project management provides organization and transparency throughout each step of the process to ensure an efficient process with complete accountability.

MECHANICAL DESIGN

Our mechanical engineers create CAD installation designs of a customer’s full packaging line and implement those plans from start to finish.

ELECTRICAL DESIGN

We include full AutoCAD Electrical design and installation as part of our design and automation services as well as any custom electrical work needed to complete the line.

IMPLEMENTATION & COMMISSIONING PROGRAM

As the final piece of the integration process, implementation requires dedication and commitment from our whole team to deliver a successful and fully integrated packaging line.

EXPERTISE

Expertise abounds at Atlantic with a full staff of engineers, technicians, and material specialists with the knowledge and experience needed to build an integrated packaging line.

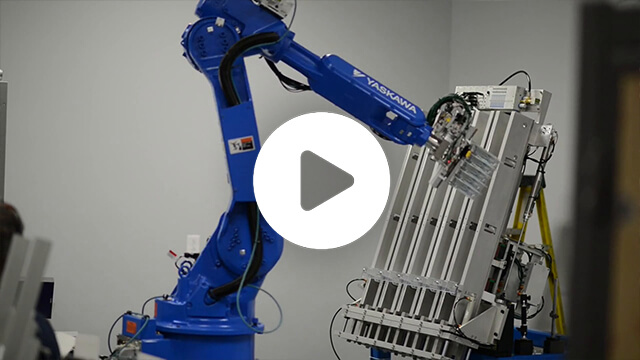

Packaging Equipment Videos

Sub Heading

Sub Heading

Sub Heading

Sub Heading

Sub Heading

Sub Heading

Sub Heading

Sub Heading

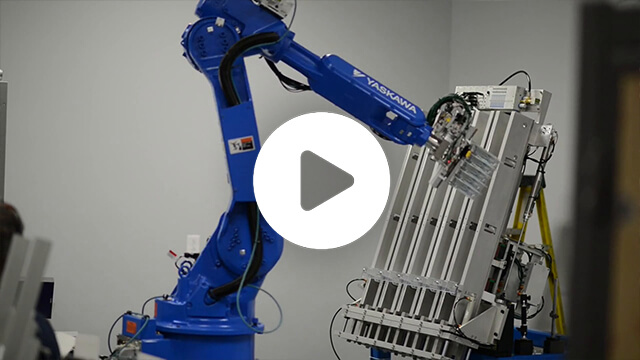

INTEGRATED PACKAGING LINES

When it comes to designing fully integrated packaging lines, Atlantic is an indispensable resource for knowledge and insight of layout, integration, mechanical and electrical components, and implementation.

Our design and automation services give us the ability to create packaging lines that match your production and meet your demands for speed, sustainability, accuracy, and performance.

Atlantic is more than an integrator. Our in-house engineers, technicians, and material specialists have tremendous expertise as well as advanced software and equipment, so we can deliver a comprehensive packaging program that doesn’t end with the equipment installation. We are dedicated to engaging in long-term partnerships with our customers to ensure their ultimate success as they continue to grow and develop.

WHAT WE OFFER

Automation, Integration, & Implementation

need help? Call us

(800) 722-5841

or

“We are dedicated to designing packaging equipment end-of-line systems in-house from start to finish so we can engage in a long-term partnership with our customers.”

Chip Bennett

VP, Equipment & Automation