When you hold a Tempest Weather System in your hands, it’s easy to focus on the sleek, all‑in‑one device: seven sensors, no moving parts, engineered for a decade of reliable performance outdoors.

But behind every new Tempest device shipped to a customer’s doorstep is a lesser‑known innovation story: how the company redesigned its packaging from the ground up to eliminate plastic, reduce waste, and align its product experience with its environmental ethos.

This is the story of how Tempest partnered with Atlantic Packaging and Cruz Foam to create a compostable and recyclable protection system strong enough for their advanced weather technology, and elegant enough to elevate the unboxing experience.

Weather Tech with a Mission

Tempest was founded on a belief that better weather data leads to a better planet. With more than 100,000 Tempest devices installed globally, the company provides hyperlocal, real‑time micro‑forecasts that benefit homeowners, government agencies, and industries ranging from energy to agriculture.

But for CTO and co‑founder David St. John, innovation extends beyond the hardware itself.

“Our products are designed to last a very long time — but our packaging shouldn’t last that long. If a device lasts ten years, there’s no reason the packaging should last hundreds.”

That idea became the catalyst to pursue a next‑generation packaging solution.

Ready for the Journey

Tempest devices are engineered for extreme outdoor environments, but also need to withstand the unpredictable shipping journey to reach customers doorsteps. Boxes can be dropped, compressed, tossed, or stacked during shipping in ways no outdoor environment would ever replicate.

Earlier packaging versions included molded pulp and then expanded polypropylene (EPP) foam. Each solved one challenge but created another: too fragile, too bulky, too much plastic, too high a carbon footprint.

Tempest wanted a solution that met three uncompromising criteria:

- Exceptional protective performance

- A refined, premium unboxing experience

- Zero plastic with fully recyclable or compostable materials

That’s when Cruz Foam entered the picture.

Why Cruz Foam Made the Cut

After testing multiple eco-friendly options, including compostable foams, molded pulp variations, starch materials, and more, Tempest reached out to Atlantic Packaging for help sourcing an environmentally-friendy foam insert to replace their EPP Foam solution.

Atlantic worked with Tempest to test Cruz Foam, a protective material made from upcycled food waste. The result was exactly what the team had been searching for:

“It provides all the cushioning of a plastic foam, but it’s upcycled and completely compostable. Once we found Cruz Foam, we knew we’d found the right direction.”

But having the right material was only the beginning.

To make the solution a reality, Tempest needed help to prototype, engineer, and scale the packaging design.

Engineering the Solution With Atlantic Packaging

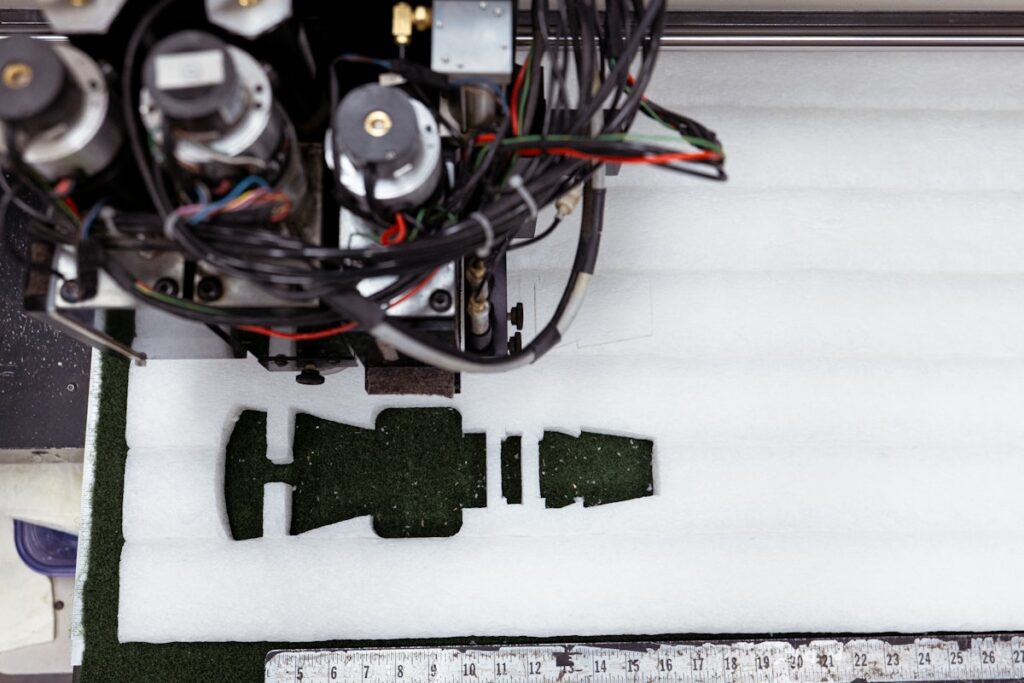

Working with Atlantic’s sustainability team, Packaging Solution Center, and converting engineers, Tempest began a collaborative R&D process that included sketching, prototyping, refining, and pressure‑testing designs to get them just right.

The challenge was big: replicate the performance of a multi‑piece molded plastic foam cradle, using a compostable material with a completely different behavior profile. The solution became a beautiful one: a layered block‑and‑brace system

Each component of the Cruz Foam insert was precision‑cut, shaped, and arranged to hold:

- the Tempest unit

- the hub

- all accessories

And all these needed to be snugly and securely in place, with everything separating cleanly for composting or curbside recycling.

A Surprise Discovery

Early prototypes were glued together with conventional adhesives, but that created compostability issues. While exploring alternatives, an Atlantic engineer tried something unconventional:

“All it took was warm water. The layers stuck together better than any glue.”

Cruz Foam bonds naturally under the right moisture conditions, eliminating the need for synthetic adhesives altogether – a win for sustainability and production simplicity.

Local Sourcing = Less Shipping, Less Carbon, More Control

By transitioning away from imported foam, Tempest reduced both costs and environmental impact. Cruz Foam and the corrugated boxes are produced in the U.S., dramatically cutting shipping emissions and improving lead times.

For Tempest, it meant:

- More agile inventory

- Lower total freight costs

- Reduced carbon footprint

- A fully domestic supply chain for their packaging

A Better Unboxing, Designed to Disappear

The final Tempest packaging solution checks every box:

- 100% plastic‑free

- Fully compostable Cruz Foam interior

- Curbside‑recyclable exterior

- A premium, thoughtfully designed unboxing experience

- A protection system engineered specifically for a rugged, high‑value device

And best of all? It aligns perfectly with Tempest’s mission.

“We started with our flagship product, but now we’re looking at all our packaging with the same lens. This is just the beginning.”

Partnership as a Path to Progress

The Tempest x Atlantic Packaging collaboration is a powerful example of what can happen when a brand, a material innovator, and a packaging engineering team work as true partners.

Everyone brought something essential:

- Tempest brought clarity of mission and deep technical requirements.

- Cruz Foam brought cutting‑edge material science.

- Atlantic brought design expertise, sustainability leadership, and the ability to engineer at scale.

Together, they created a packaging system built not to last, but to return gracefully to the earth.

Because in the world Tempest imagines, the devices should last a decade.

The packaging should not.