Beverage Packaging

Optimize to Reduce Material & Improve Performance

Technically Advanced, Sustainable Packaging for the Beverage Industry

We optimize high-quality packaging for optimal product protection with minimal material usage.

Eliminate Damage

Maximize Load Containment

Monitor Stretch Wrapping

Want to reduce secondary packaging and still protect your unit load?

We can help if:

- Your last attempt to reduce secondary packaging failed

- You have trouble seeing the big picture of load containment

- You don’t think it’s possible to save money with high-performance film

- You want to know what you can learn from a site audit

- You need testing to prove load containment standards

- You need a way to monitor stretch wrapping performance

How Can We Help You?

Sustainably Optimize Your Beverage Packaging

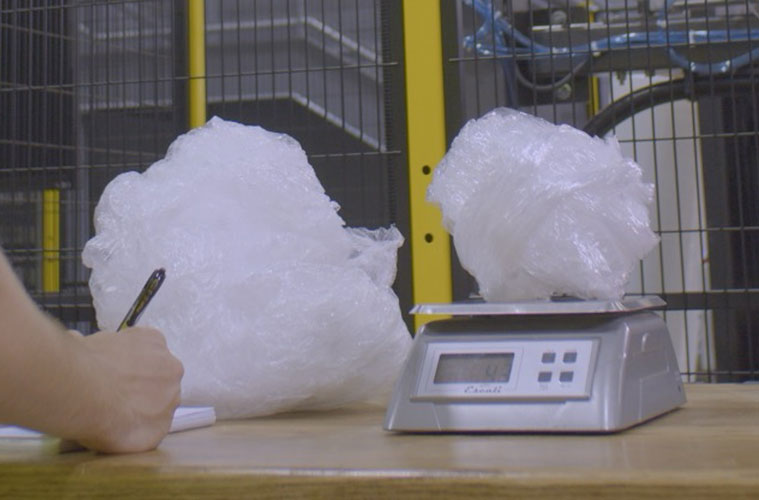

Brands are making huge strides in sustainability using less material in product packaging. But if you’re not careful, this reduction in packaging can lead to load failure. We can help you find out why loads are failing and how you can prevent product damage during transportation at the Packaging Solution Center.

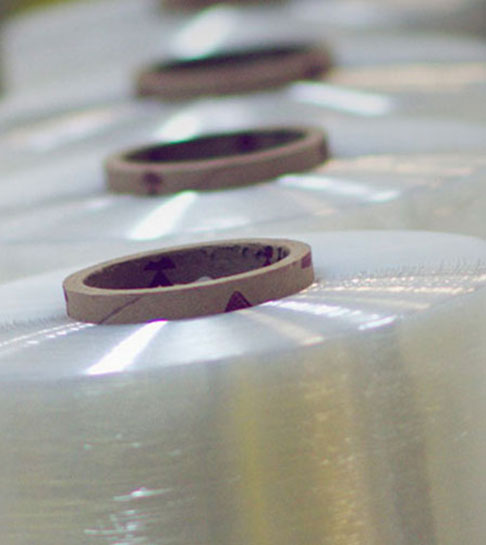

Our scientific approach to packaging allows us to optimize, standardize, and validate your packaging for transportation to minimize product damage, material usage, and packaging spend. The MUST Program brings consistency and monitoring to stretch wrapping for maximum load containment with optimal film use.

Another innovative solution we have helped pioneer for the beverage industry is Canopy™, a curbside-recyclable alternative to PE shrink film for tray bundling. Canopy™ is here to improve the circularity of your packaging operations, and Canopy™ Equipment can be retrofitted to existing bundling machinery or installed as a dedicated high-speed bundler.

We also have a solution if you’re looking to eliminate single-use plastics from your consumer-destined beverage packaging. Fishbone is the recyclable can carrier system that replaces PE 6-pack rings and HDPE caps.

Beverage Industry Videos

Sub Heading

Sub Heading

Sub Heading

Sub Heading

Sub Heading

Sub Heading

Sub Heading

Sub Heading

Sub Heading

Sub Heading

WHAT WE OFFER

Sustainable, Optimized Beverage Packaging Solutions

need help? Call us

(800) 722-5841

or

“Our ability to understand the unique shipping needs of our customers places us in the best position for effectively wrapping pallet loads at the lowest possible cost.”

Ric Lee

Director – MUST Stretch Film Management System