Lifecycle Analysis

Analysis for Packaging Savings

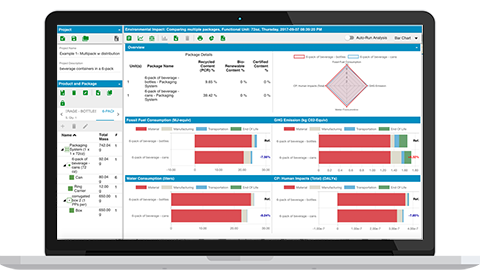

Atlantic has invested in Compass software from Trayak to provide accurate LifeCycle Analysis for packaging savings.

The Sustainable Packaging Coalition partnered with Trayak to develop this software that is now used as a standard in the industry.

Atlantic uses this software to develop models for customer sustainability savings. We try to capture as many of the components and inputs as possible to show the most accurate picture of these gains. For example, when we model stretch film savings, we not only capture the actual film savings, but include savings from cores, other packaging, and the pallets.

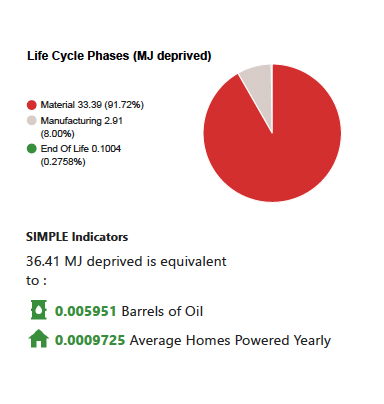

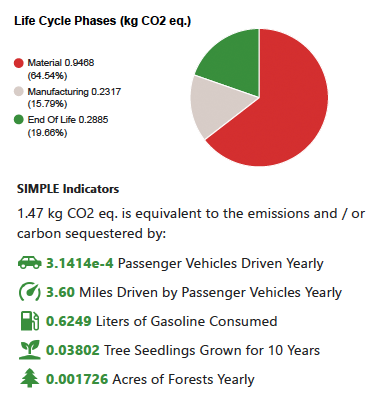

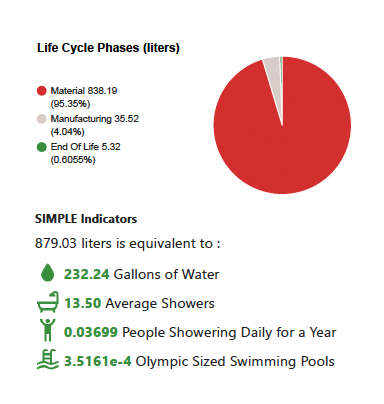

An example of this calculation for one pound of stretch film is shown below. We also have included an assessment for a 20” film core along with core plugs below.

Compass Software

COMPASS is a life cycle analysis tool developed by the Sustainable Packaging Coalition in a collaborative process.

The tool was created to incorporate environmental performance criteria into the concept development and material selection stages of package design. Data is verified by third party and prominent brand owner companies. Leading companies and educational institutions throughout the world use COMPASS to assess their package designs for sustainability.

Total Environmental Impact

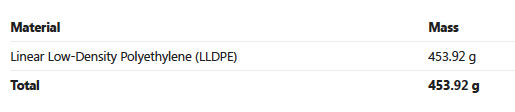

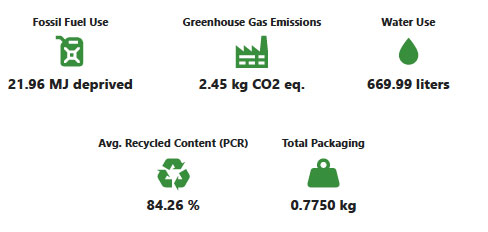

Calculation for 1lb of Stretch Film

This section shows the total impact for each of the selected indicators used for the Life Cycle Analysis. Each indicator is composed of the material extraction, manufacturing, transportation, end of life, and use phase impacts. This will allow you to determine which life cycle phase has the greatest impact. Note: The material phase measures the environmental footprint of extracting and processing materials. The manufacturing phase calculates the impact of the manufacturing or conversion processes that companies use to add value and create the package or product. Use phase includes the environmental impact during the useful life of the package/product. Typically, the use phase impact is due to the consumption of resources like electricity, fuel, or other consumables. For the transportation phase, the impact is calculated based on the mode of transportation (road, rail, air, sea) as well as the distances travelled. The end of life impact calculation incorporates the most likely fate of the product/package and its components based on typical curbside municipal waste management. Typical percentage rates for region based recycling, incineration, and landfill are used to calculate the impacts.

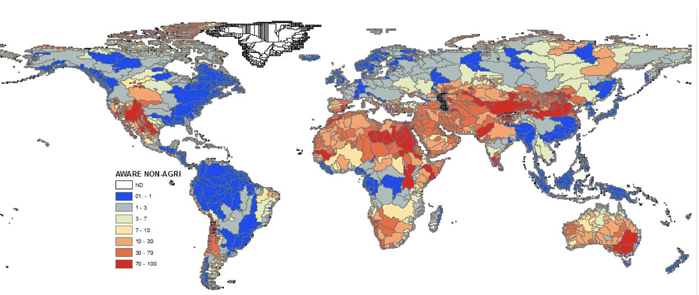

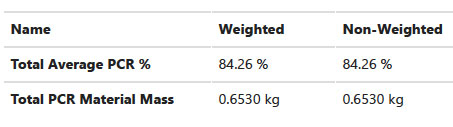

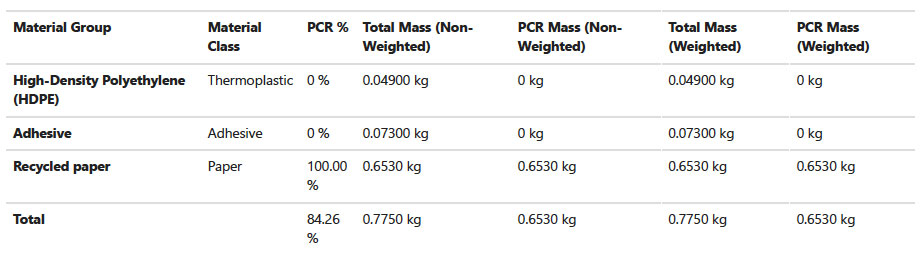

Calculation for 20” Film Core & Core Plugs

This report is used to roll up the chosen sustainability indicators and attributes for the selected portfolio of packages/products. It provides overall actionable metrics to understand the sustainability performance of a company’s portfolio and can be useful in making macro level decisions affecting a range of packages/products. In addition, it can be used alongside the production volumes of each package or product to provide weighted and non-weighted metrics.

need help? Call us

(800) 722-5841

or