by ATLant1c-pKg | Dec 1, 2016 | Packaging Equipment and Materials

Atlantic Packaging is honored to be chosen as Clysar’s Distributor of the Year for 2016. Clysar presented this award at their annual distributor meeting and reception, held at the Shedd Aquarium in Chicago, in conjunction with Pack Expo...

by ATLant1c-pKg | Oct 18, 2016 | Packaging Equipment and Materials

One of the dominant trends in packaging over the last decade involved reducing primary and secondary packaging materials to save resources and cut costs. Think about the super-thin plastic water bottles and the smaller caps that are so prevalent today. Or cases of...

by ATLant1c-pKg | Apr 26, 2016 | Packaging Equipment and Materials

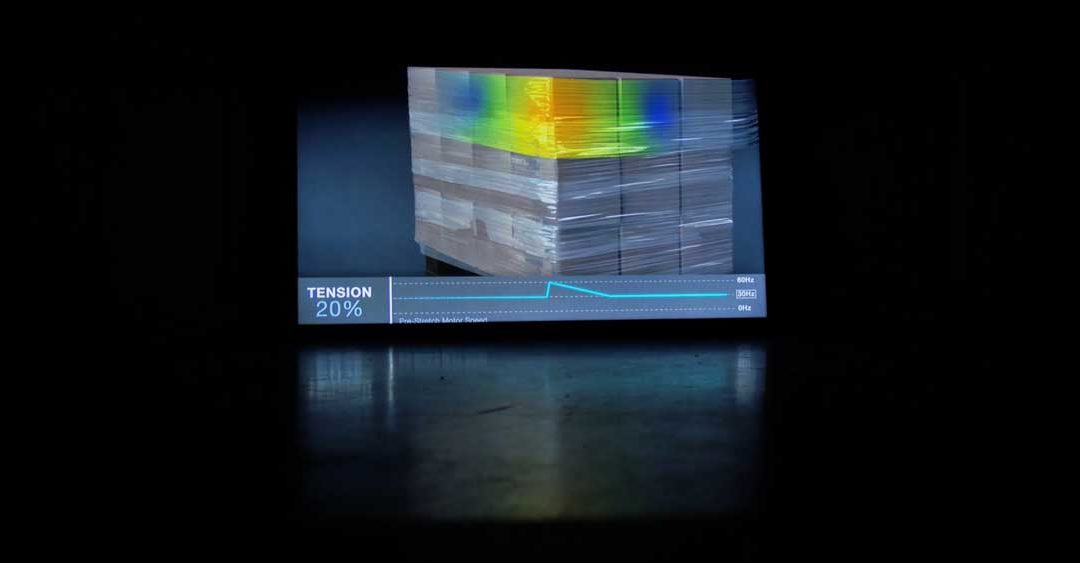

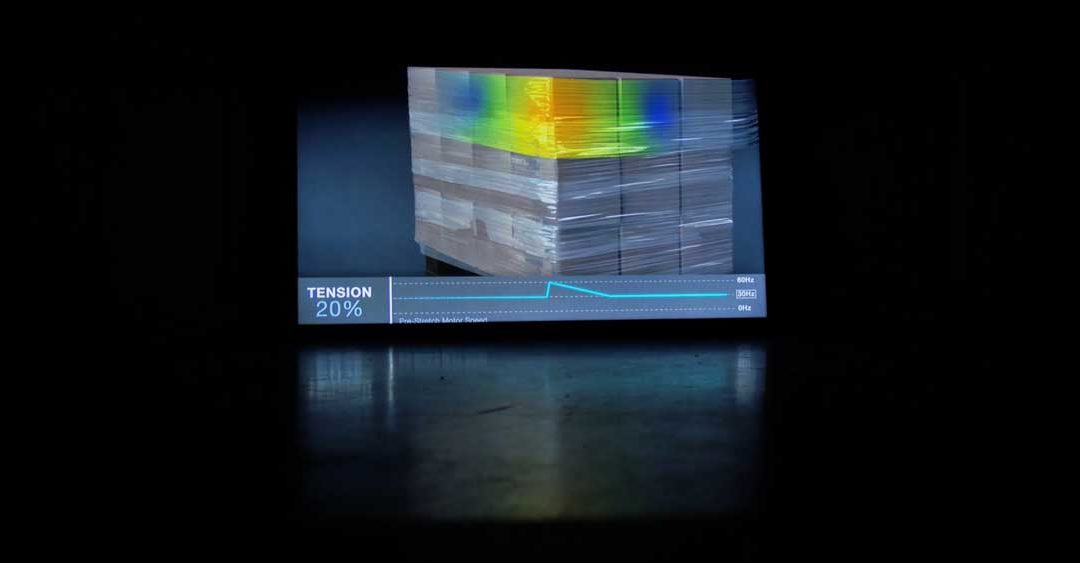

Over the last decade, we’ve hired material and equipment experts in-house to help give our customers an edge when it comes to choosing the right films and the right equipment settings for their specific applications. We’ve seen first-hand how successful...

by ATLant1c-pKg | Apr 4, 2016 | Packaging Equipment and Materials

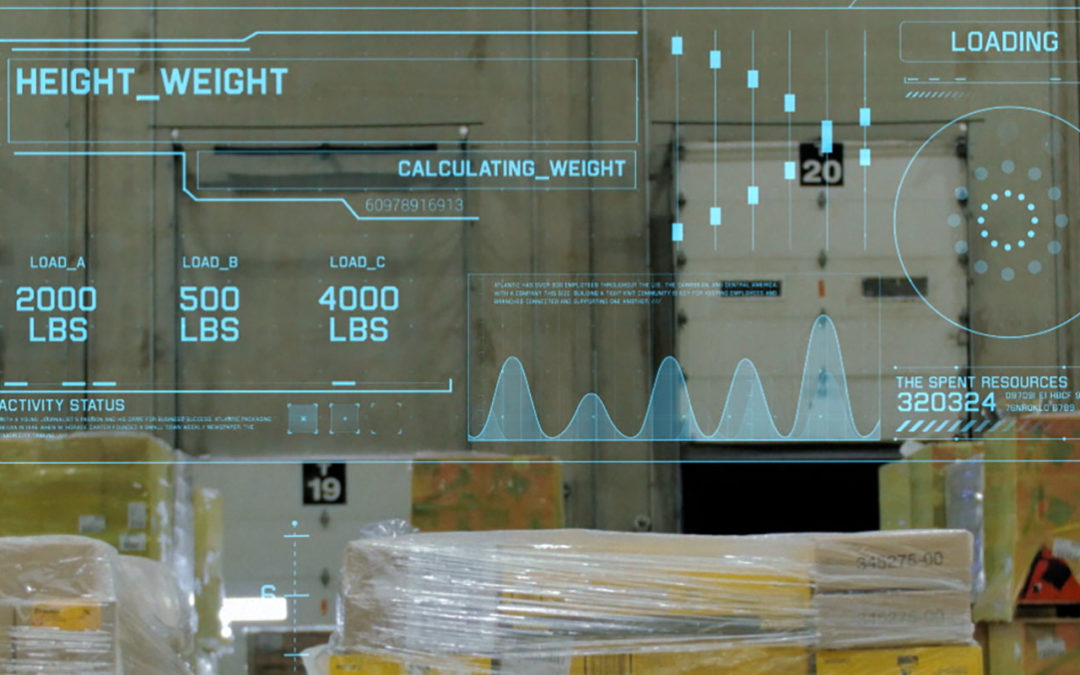

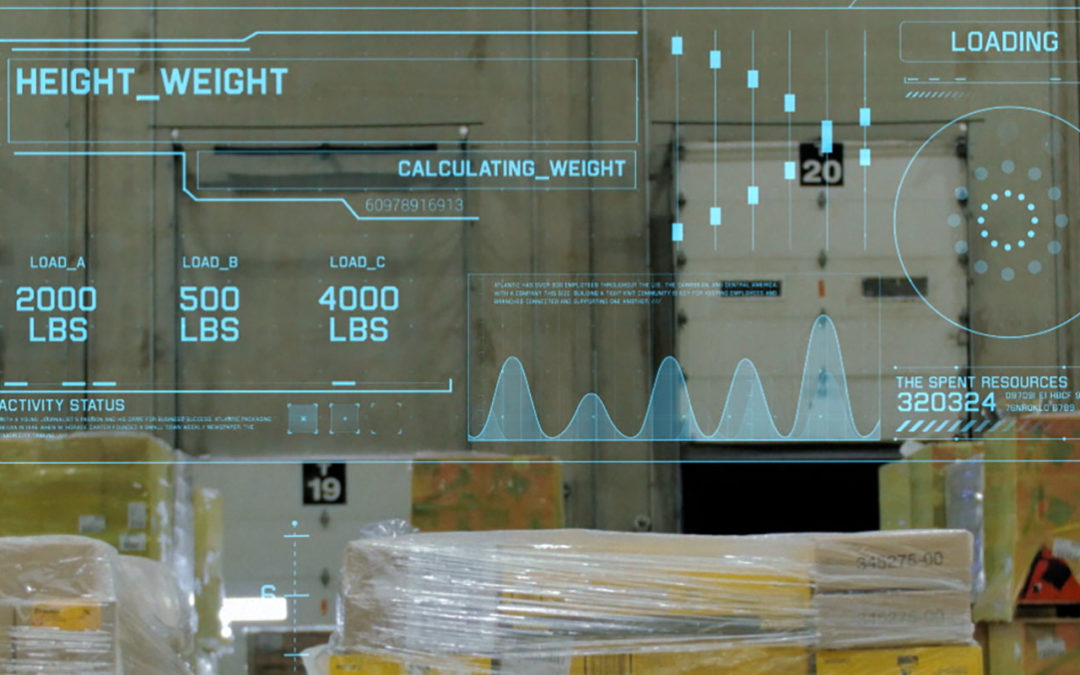

Distribution centers handle a wide variety of products that need to be sorted, packed, and shipped throughout the day. This variety presents a challenge when it comes to stretch wrapping. The loads coming through the wrapper vary in size and weight from pallet to...

by ATLant1c-pKg | Jun 29, 2015 | Industries Served, Material Usage Standards Tracking, Package Design and Testing, Packaging Equipment and Materials, Sustainability in Packaging

Have you noticed changes in plastic water bottles over the last several years? Smaller caps, smaller printed labels, and lighter plastic are a few of the ways that beverage companies are reducing waste in their packaging. They are also bundling their cases without...