by ATLant1c-pKg | Nov 8, 2018 | Packaging Equipment and Materials, Poultry Equipment Spotlight

SPOTLIGHT ON THE KEYMAC K101 AUTOSLEEVE The Keymac K101 Carton Sleever is a fully automatic sleeving machine ideal for the ready meal market. With low maintenance requirements and reduced running costs, this model adds speed, efficiency, and accuracy to your...

by ATLant1c-pKg | Oct 2, 2018 | Packaging Equipment and Materials, Poultry Equipment Spotlight

SPOTLIGHT ON THE COMBI WASHDOWN ERGOPACK SYSTEM For full end-of-line case packaging in washdown environments, the Combi Ergopack is the ideal system. It combines a case erector, an ergonomic hand pack station, and a case sealer in a sanitary design perfect for...

by ATLant1c-pKg | Aug 20, 2018 | Packaging Equipment and Materials, Poultry Equipment Spotlight

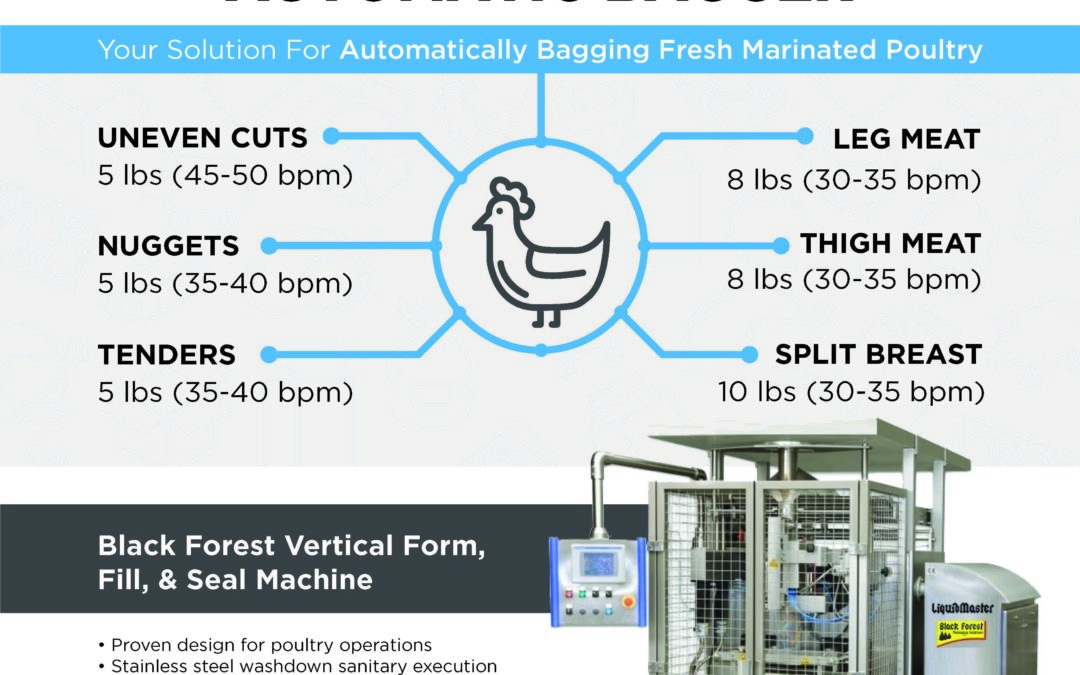

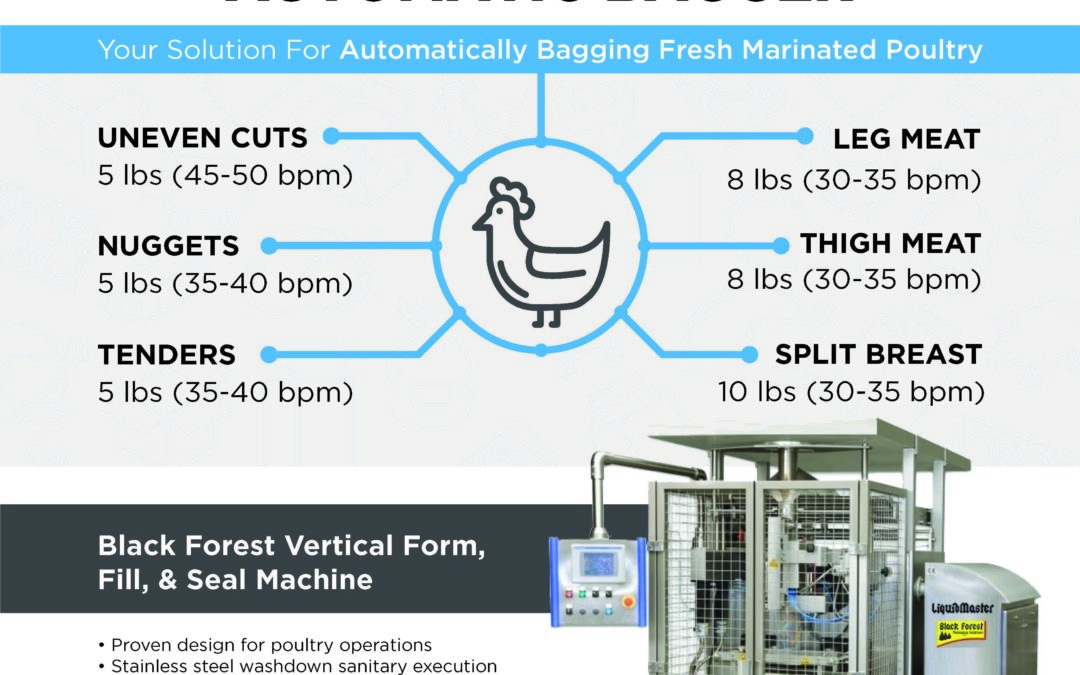

We have Your Solution for Automatically Bagging Fresh Marinated Poultry. There are unique challenges when it comes to bagging marinated poultry cuts. In particular, it’s difficult to remove air and get a clean seal when dealing with marinade and automated...

by ATLant1c-pKg | Jul 11, 2018 | Packaging Equipment and Materials, Poultry Equipment Spotlight

SPOTLIGHT ON THE BANDRITE SEALER WITH INTEGRATED HP PRINTER For sealing bagged fresh food, you need an easy-to-use and reliable band sealer. And with the rise of product traceability requirements, you also need an accurate timestamp that works with your system....

by ATLant1c-pKg | May 30, 2018 | Packaging Equipment and Materials, Poultry Equipment Spotlight

Spotlight on Code Tech TIJ Printers When it comes to marking and coding in your processing environment, Atlantic offers a Code Tech thermal ink jet (TIJ) system that rivals any continuous ink jet (CIJ) you may have. Our Code Tech printers are: IP65 rated Washdown...

by ATLant1c-pKg | Apr 26, 2018 | Packaging Equipment and Materials, Poultry Equipment Spotlight

Spotlight on Pearson Bag Inserters Atlantic has been working in the food processing industry for over 40 years, servicing our customers with materials, equipment, and service that helps keep your production running smoothly, safely, and efficiently. Over all...