by ATLant1c-pKg | Apr 4, 2017 | Package Design and Testing

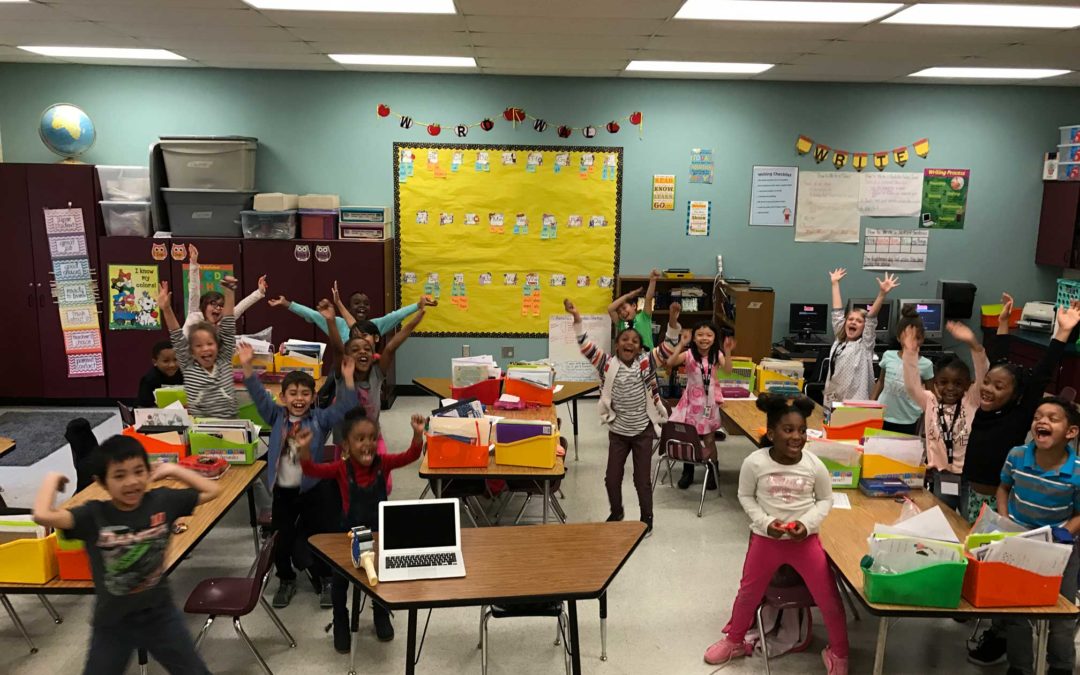

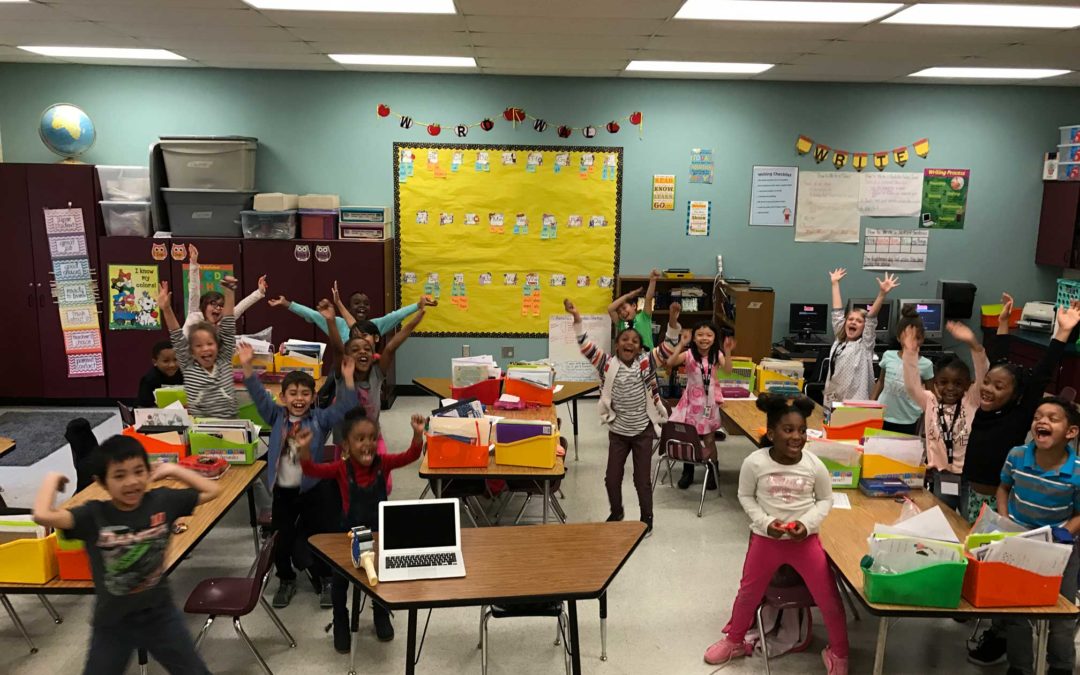

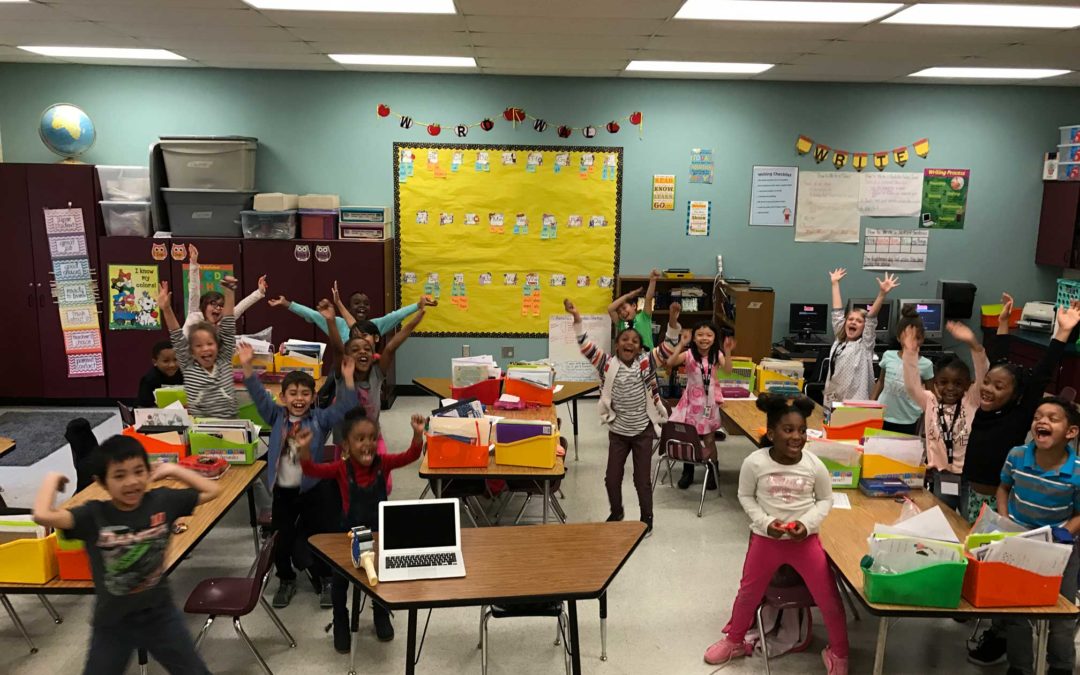

Packaging is an important part of our everyday life, even if we don’t realize it. From an early age, we’re handling packaging and making decisions about it almost daily. Picking out toys and household items, buying food at the grocery store,...

by ATLant1c-pKg | Mar 17, 2017 | Package Design and Testing

“Set it and forget it” is no longer the mantra of the day when it comes to stretch wrapping. With smart technology and high speed production lines fast becoming the norm, stretch wrapping has evolved into a sophisticated operation able to keep up with even...

by ATLant1c-pKg | Nov 1, 2016 | Package Design and Testing, Sustainability in Packaging

Product manufacturers are always looking for ways to make their packaging greener, more efficient, and less costly. Greener packaging is an important goal in all aspects of product creation, from how you receive parts from your vendors to how you package and ship to...

by ATLant1c-pKg | Sep 8, 2015 | Atlantic Packaging, Package Design and Testing

Maximizing package density for efficiency, ease of packing, and faster packing times. Across the board, our customers care very much about two particular things when shipping their products: 1. Protecting the product from any damage during transit and storage, and2....

by ATLant1c-pKg | Jun 29, 2015 | Industries Served, Material Usage Standards Tracking, Package Design and Testing, Packaging Equipment and Materials, Sustainability in Packaging

Have you noticed changes in plastic water bottles over the last several years? Smaller caps, smaller printed labels, and lighter plastic are a few of the ways that beverage companies are reducing waste in their packaging. They are also bundling their cases without...

by ATLant1c-pKg | Nov 6, 2013 | Package Design and Testing, Packaging Products

Good design is simple, elegant and efficient. Here at Atlantic Packaging, we believe that great products deserve great packaging. This is why we have a dedicated custom packaging design lab in our Youngsville, North Carolina facility. We develop packaging designs that...