Protect Your Product

Packaging for Paper Mills

Need creative solutions to protect your paper rolls?

- Film and roll wrap application that protect during handling, storage, and delivery

- Repulpable splicing tape for a recyclable product

- Just in time inventory management

- Custom cut corrugated roll headers plus radial axial wrap

- Roll labels and labeling systems

- Industry insight and expertise

Paper Making Industry Videos

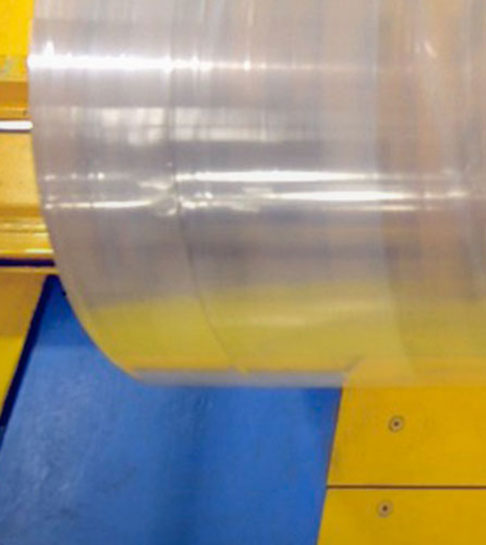

ROLL WRAP

Atlantic roll wrap technicians bring decades of experience working at all angles of this packaging process. Our collective experience provides us with a comprehensive understanding of our customer’s needs and all the factors throughout the process that can affect the performance and outcome of the final product.

WE PROTECT YOUR PRODUCT

The bottom line is that we offer high performance film wrap for optimal protection of your product through all stages of handling, delivery, and storage. We work with large-scale paper mills and are adept at handling roll wrap systems and materials to protect rolls up to 6′ in diameter and up to 5,000 lbs.

We supply film that is optimized for specific applications and we propose systems that will be most effective to the customer’s desired outcome. To this end, we offer radial wrap, axial wrap or a radial axial package that will fully enclose the roll in protective film to help it withstand handling on the forklifts, exposure to weather, non-optimal conditions, and storage with other product.

WE HELP SOLVE PROBLEMS

Where Atlantic’s added value lies with our customers is in the creative solutions we can offer to help solve problems that may be causing damaged freight or throughput problems.

Our knowledge of the equipment, the systems, and the materials together with our sensitivity regarding our customers’ unique needs and budget concerns make Atlantic an invaluable partner when it comes to roll wrap.

FILM EXPERTISE

Atlantic prioritizes our investment in people and expertise. This expertise gets put to work for our customers in how we approach a new project and how we adapt to new challenges and changes in the industry.

WE SEE THE BIG PICTURE

When we meet with a paper mill as a new customer, the first thing we do is perform an audit of their current process. Our technicians spend time in the facility to assess what the exact product is; what type of equipment is being used and what condition that equipment is in; where the product is being shipped; what the shipping and packaging expectations are; and what the current conditions of the process are. Is there damaged freight, are there customer complaints, or is the facility experiencing frequently repeated issues?

We are often able to identify the root cause of existing issues or present an optimized process that will improve efficiency and ultimately save money for our customer.

FOCUS ON PROBLEM SOLVING

Our problem solving process relies on an open minded, creative outlook. We may set up controlled test environments so that we can test and prove the efficacy of our solutions before any changes are implemented. The insight gained through the audit and testing process helps us work toward the best possible formula to match the equipment with the right film and materials.

Our working knowledge of your overall systems, equipment, and product together with our long term investment in your success is what makes Atlantic your ideal partner in roll wrap applications.

ROLL HEADERS

CUSTOM HEADERS

Very few machines exist in the U.S. that can cut custom headers to protect raw material paper rolls out of the mills, and Atlantic has one of them. (Learn more: Atlantic Industrial Converting) We offer an incredible opportunity for paper mills to get the exact roll headers they need to package and protect their entire range of product going out the door.

OPTIMAL PROTECTION FOR YOUR PRODUCT

Roll headers that are custom cut to match your product serve as valuable protection during freight and storage. Any reduction in damaged freight means better efficiency, lower costs, and better customer service from the mill.

Our customers trust Atlantic to cut, deliver, and manage the inventory on roll headers. We have earned this trust through years of on-time, high quality, and accurate service.

WE ARE YOUR SOURCE

Our ability to cut and deliver custom roll headers for paper mill products together with our roll wrap film, equipment, and inventory management provides a great value for our customers. Add in our dedicated sales, technical, and customer service team, and Atlantic becomes a one-stop packaging source for paper mill facilities.

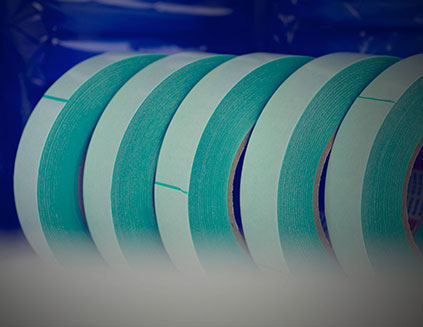

REPULPABLE TAPES

Atlantic can provide paper mills with repulpable splicing tape in conjunction with our other offerings including roll wrap, film wrappers, roll headers, labels, and inventory management.

CLOSING THE LOOP

Using repulpable splicing tape means that raw material is recyclable and goes back into the process, closing the loop on the mills’ waste stream. This is extremely advantageous for our paper mill customers in terms of improving sustainability, reducing waste, and increasing efficiency.

Paper mills can count on Atlantic as a steady and reliable source of repulpable splicing tape to help ensure that systems run continuously and without challenges to the throughput process.

INVENTORY PROGRAM

Atlantic provides our customers with reliability and security of supply. We take more product in our warehouses than almost any other major distributor in the U.S. plus we have some of the best service and supply connections in the industry.

NO MORE THROUGHPUT PROBLEMS

The depth of our supply and inventory program means that your paper mill is not at danger of running out of film or materials and having to stop operations while you wait for a shipment. Atlantic has the people, the warehouses, and the trucks necessary to deliver on a quick turnaround time.

Our total team approach and our commitment to long term customer relationships means that we go the extra mile needed to ensure that our customers get what they need, when they need it.

INVENTORY MANAGEMENT ON-SITE OR OFF-SITE<

At Atlantic, our goal is to help meet the very specific needs of each of our customers. That may mean that we take over inventory management in their warehouse or that we manage a customer’s inventory and storage in our own warehouse space. We can also offer Just In Time (JIT) inventory management when that is required.

PARTNER UP WITH ATLANTIC

Having Atlantic as a packaging partner on equipment, systems, materials, and inventory means that we have a great deal of context for your overall operations, allowing us the insight to effectively manage your inventory, keep costs down, and keep your facility running at optimal performance.

See more information about our Inventory Management Program.

ROLL LABELS

In addition to our capabilities as far as packaging, materials, equipment, and inventory management, Atlantic also provides a robust labeling service that helps round out our offerings for paper mills.

Let Atlantic be your single source for the equipment and materials needed to get your product out the door and to its final destination safely and efficiently, with reduced threat of damage or loss.

LABELING AND SYSTEMS

Atlantic can incorporate a labeling system with your roll wrap equipment and also manage your label supply and inventory. Our ability to provide labeling systems and labels lets our paper mill customers rely on Atlantic for the materials and equipment needed throughout the full packaging process.

Trust Atlantic to be your packaging partner. We invite you to contact our expert sales team to learn how our capabilities, materials, and inventory supply and management services can benefit your roll packaging operation.

Atlantic’s dedication to the industry gives you the necessary insight to identify and solve the problems that paper mills live with everyday.Atlantic’s comprehensive roll wrap program covers all facets of dry-end paper production.

Roll Wrap

Roll Wrap Roll Headers

Roll Headers Wide Web Printing

Wide Web Printing